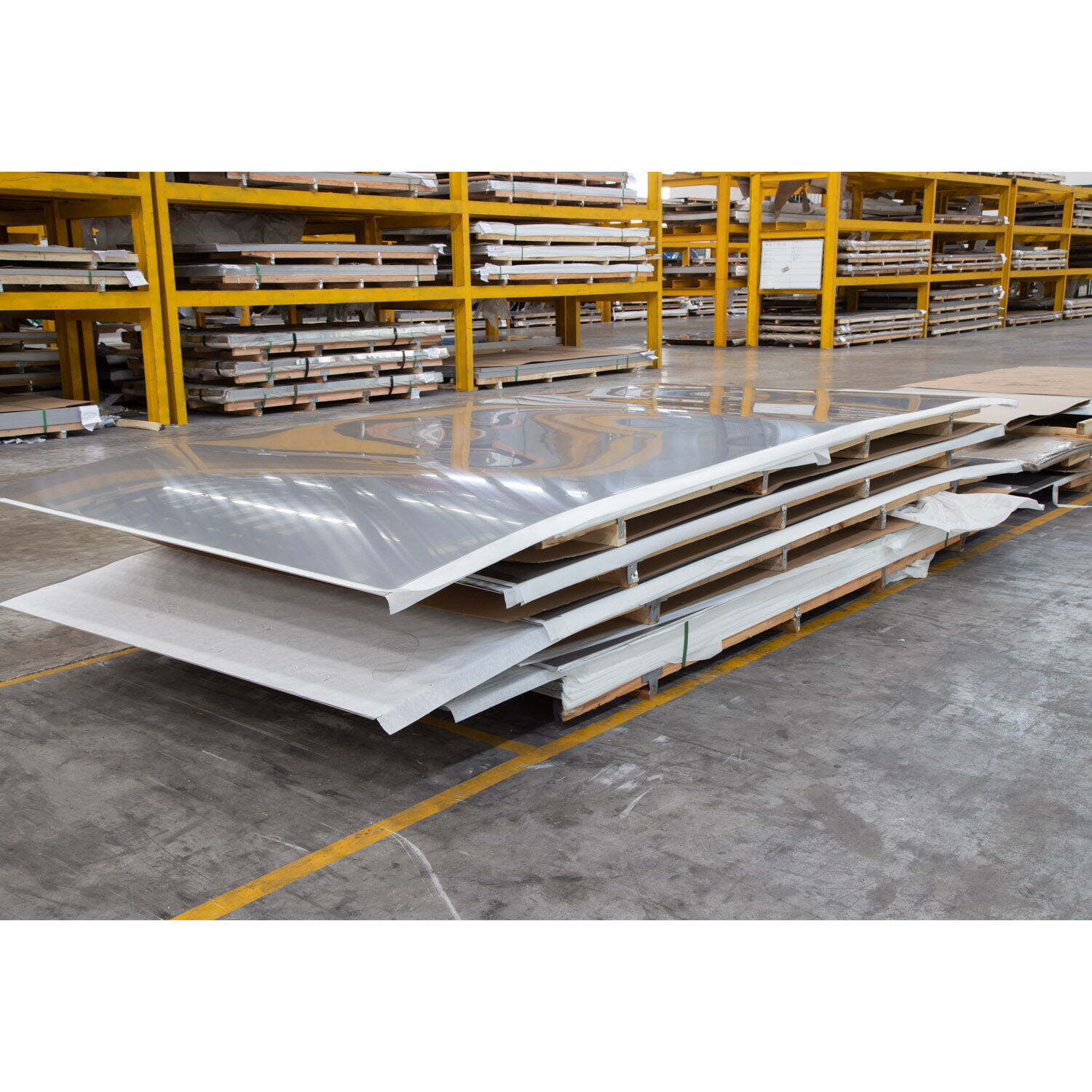

cold rolled stainless steel strip

Cold rolled stainless steel strip represents a sophisticated metallurgical product characterized by its superior surface finish and precise dimensional control. This material undergoes a specialized manufacturing process where stainless steel is passed through rollers at room temperature, resulting in enhanced mechanical properties and improved surface quality. The process significantly reduces the thickness while simultaneously increasing the strength and hardness of the material. These strips are available in various grades, including austenitic, ferritic, and martensitic, each offering specific performance characteristics. The cold rolling process creates a smooth, bright finish and ensures tight thickness tolerances, making these strips ideal for applications requiring aesthetic appeal and dimensional accuracy. In industrial applications, cold rolled stainless steel strips are extensively used in automotive components, architectural facades, medical instruments, and consumer appliances. The material's inherent corrosion resistance, combined with its excellent formability and weldability, makes it a versatile choice for numerous manufacturing processes. Modern cold rolling techniques also allow for custom width, thickness, and edge conditions, providing manufacturers with flexibility in their production requirements.