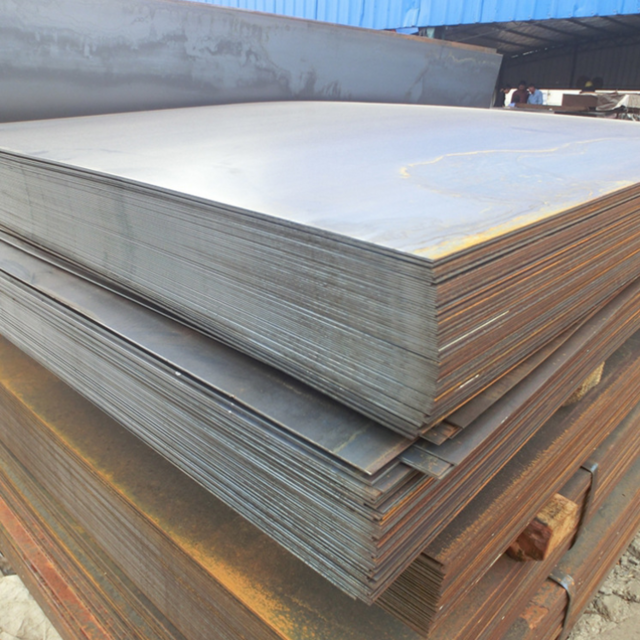

thin stainless steel strips

Thin stainless steel strips represent a versatile and essential component in modern manufacturing and industrial applications. These precision-engineered materials are produced through advanced rolling processes that ensure consistent thickness, superior surface finish, and exceptional mechanical properties. Typically ranging from 0.05mm to 3mm in thickness, these strips combine the inherent corrosion resistance of stainless steel with enhanced flexibility and formability. The manufacturing process involves careful control of temperature, pressure, and cooling rates to achieve optimal grain structure and mechanical characteristics. These strips excel in applications requiring high strength-to-weight ratios, excellent corrosion resistance, and precise dimensional tolerances. They are widely utilized in automotive components, electronic devices, medical instruments, and architectural applications. The strips undergo rigorous quality control measures, including surface testing, dimensional verification, and material composition analysis to ensure they meet industry standards and specifications. Their versatility extends to both decorative and functional applications, making them ideal for various manufacturing processes including stamping, forming, and precision cutting operations.