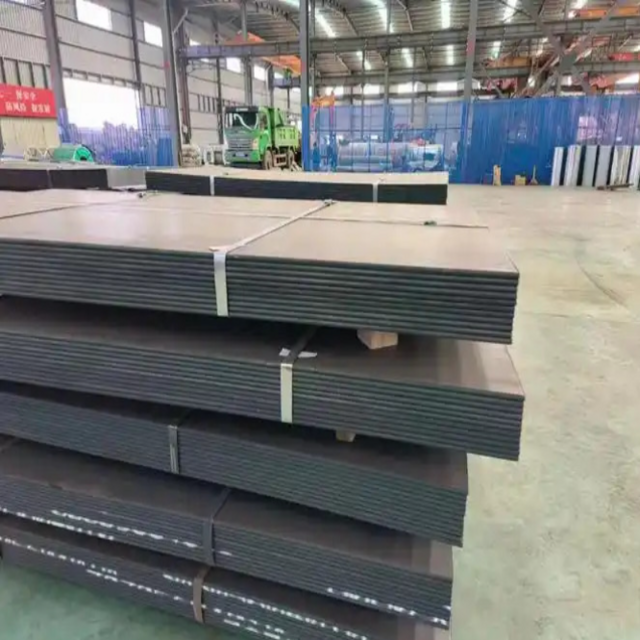

stainless steel spring steel strip

Stainless steel spring steel strip represents a highly engineered material that combines the corrosion resistance of stainless steel with the exceptional elastic properties required for spring applications. This versatile product is manufactured through a precise cold rolling process, resulting in a material that exhibits superior tensile strength, excellent fatigue resistance, and remarkable dimensional stability. The strips are available in various grades, thicknesses, and widths to accommodate different industrial requirements. What sets this material apart is its ability to maintain consistent performance under varying temperatures and stress conditions, making it ideal for demanding applications. The manufacturing process involves careful control of chemical composition, heat treatment parameters, and surface finish to ensure optimal spring properties. These strips demonstrate excellent shape memory characteristics, allowing them to return to their original form after deformation within their elastic limit. Their corrosion-resistant properties make them particularly valuable in environments where exposure to moisture, chemicals, or atmospheric conditions could compromise standard spring materials. The material finds extensive use in automotive components, electronic devices, medical instruments, and various precision mechanisms where reliable spring action and durability are essential.