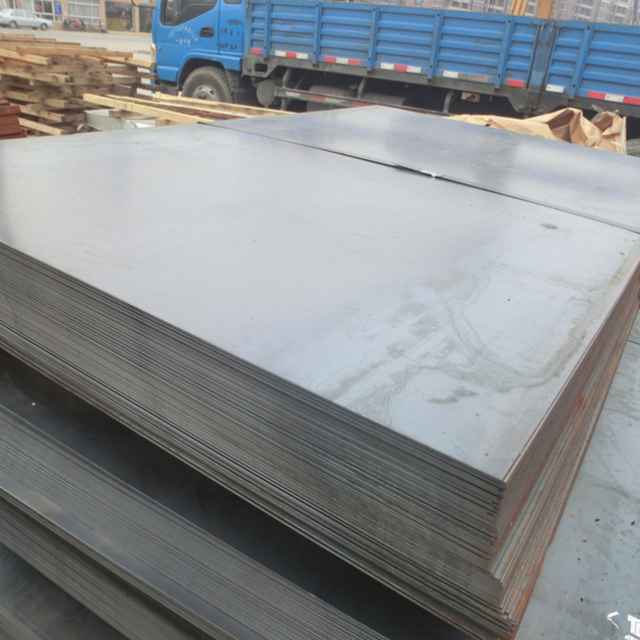

steel strip coil

Steel strip coils represent a fundamental component in modern manufacturing and industrial processes, offering versatile solutions for various applications. These precision-engineered products consist of continuous lengths of steel material wound into a cylindrical form, combining durability with practical functionality. The manufacturing process involves carefully controlled rolling and finishing operations, ensuring consistent thickness, width, and surface quality throughout the entire length of the strip. Steel strip coils are available in various grades, thicknesses, and widths to meet diverse industrial requirements. They undergo rigorous quality control measures, including surface treatment and coating applications, to enhance their resistance to corrosion and wear. The technological features include precise dimensional tolerances, uniform material properties, and specialized surface finishes that cater to specific end-use applications. These coils serve as primary materials in automotive manufacturing, construction, appliance production, and numerous other industries where reliable, high-quality steel products are essential. The efficient coil format facilitates easy transportation, storage, and integration into automated manufacturing processes, making them a cost-effective solution for large-scale production needs.