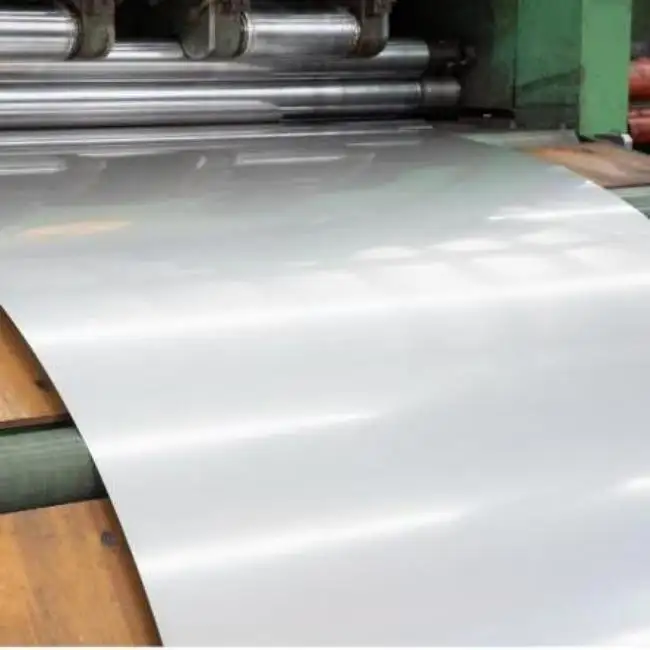

black steel strip

Black steel strip represents a versatile and essential material in modern manufacturing, characterized by its distinctive dark surface finish and exceptional durability. This specialized steel product undergoes precise processing methods, including cold rolling and surface treatment, to achieve its characteristic black oxide coating. The strip's composition typically features high-quality carbon steel as its base material, enhanced through various metallurgical processes to ensure optimal performance. The black surface coating serves multiple purposes, including corrosion resistance, improved wear protection, and enhanced visual appeal. In industrial applications, black steel strip finds extensive use in construction, automotive manufacturing, and machinery production. The material's uniform thickness and consistent surface quality make it particularly suitable for applications requiring precise dimensional tolerances. Its versatility extends to both structural and decorative applications, where the black finish provides both functional benefits and aesthetic value. The manufacturing process ensures tight control over mechanical properties, resulting in a product that maintains structural integrity while offering excellent formability. This combination of characteristics makes black steel strip an ideal choice for applications ranging from automotive components to architectural elements, where strength, durability, and appearance are crucial factors.