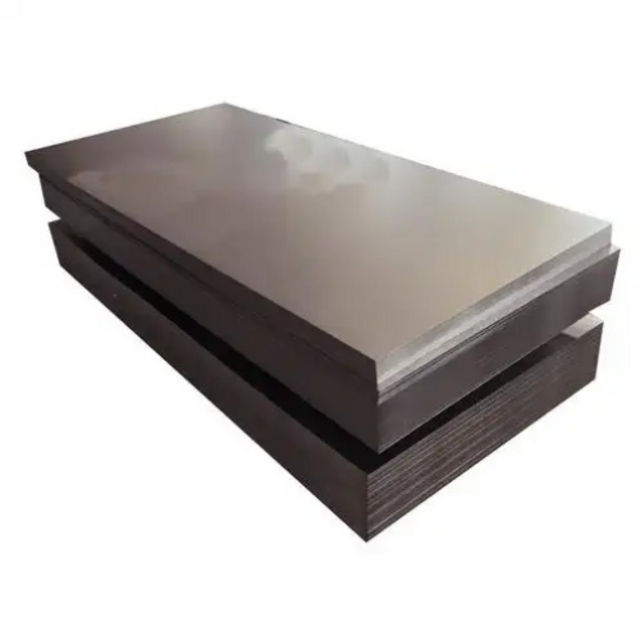

hot rolled steel strip

Hot rolled steel strip represents a fundamental product in the metal manufacturing industry, produced through a high-temperature rolling process that typically operates above the metal's recrystallization temperature. This manufacturing method involves heating steel slabs to temperatures exceeding 1,700°F (926°C), then processing them through a series of rollers that progressively reduce their thickness to create the desired dimensions. The resulting product exhibits excellent mechanical properties, including superior strength, durability, and formability. Hot rolled steel strip finds extensive applications across various industries, from construction and automotive manufacturing to industrial equipment and infrastructure development. The process creates a characteristic finish with slightly rounded edges and a mill scale surface, which is ideal for applications where precise tolerances are not critical. These strips are available in various widths, thicknesses, and grades, offering versatility for different industrial applications. The material's cost-effectiveness, coupled with its reliable performance characteristics, makes it a preferred choice for large-scale industrial projects and manufacturing processes where structural integrity is paramount.