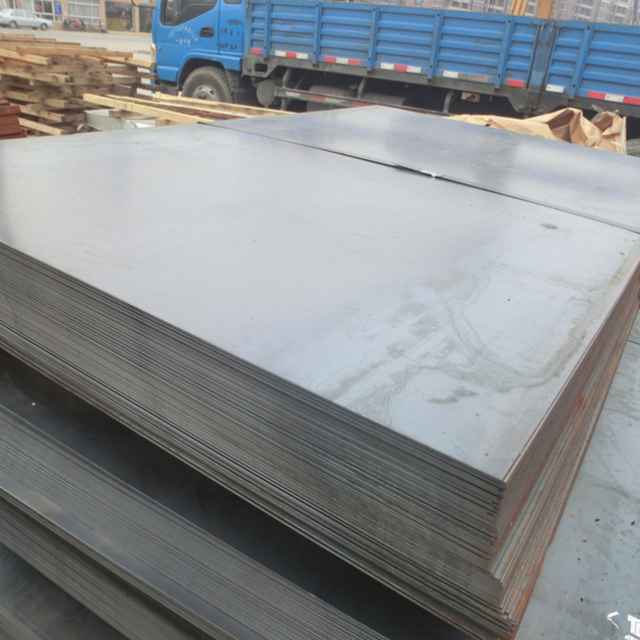

carbon steel strips

Carbon steel strips represent a versatile and essential component in modern manufacturing and industrial applications. These precision-engineered materials are produced through advanced rolling processes, resulting in thin, flexible metal strips with precisely controlled dimensions and mechanical properties. The strips are manufactured from high-quality carbon steel, containing specific carbon content that can be adjusted to meet various industrial requirements. These strips exhibit exceptional strength-to-weight ratios, remarkable durability, and outstanding formability characteristics. They are available in various thicknesses, widths, and surface finishes, making them suitable for diverse applications across multiple industries. The manufacturing process involves careful control of temperature, pressure, and cooling rates to achieve the desired mechanical properties, including tensile strength, hardness, and flexibility. Carbon steel strips are widely used in automotive components, construction materials, machinery parts, and various consumer products. They can be easily cut, formed, welded, and machined, making them ideal for both high-volume production and custom applications. The strips also demonstrate excellent resistance to wear and tear, making them suitable for demanding industrial environments.