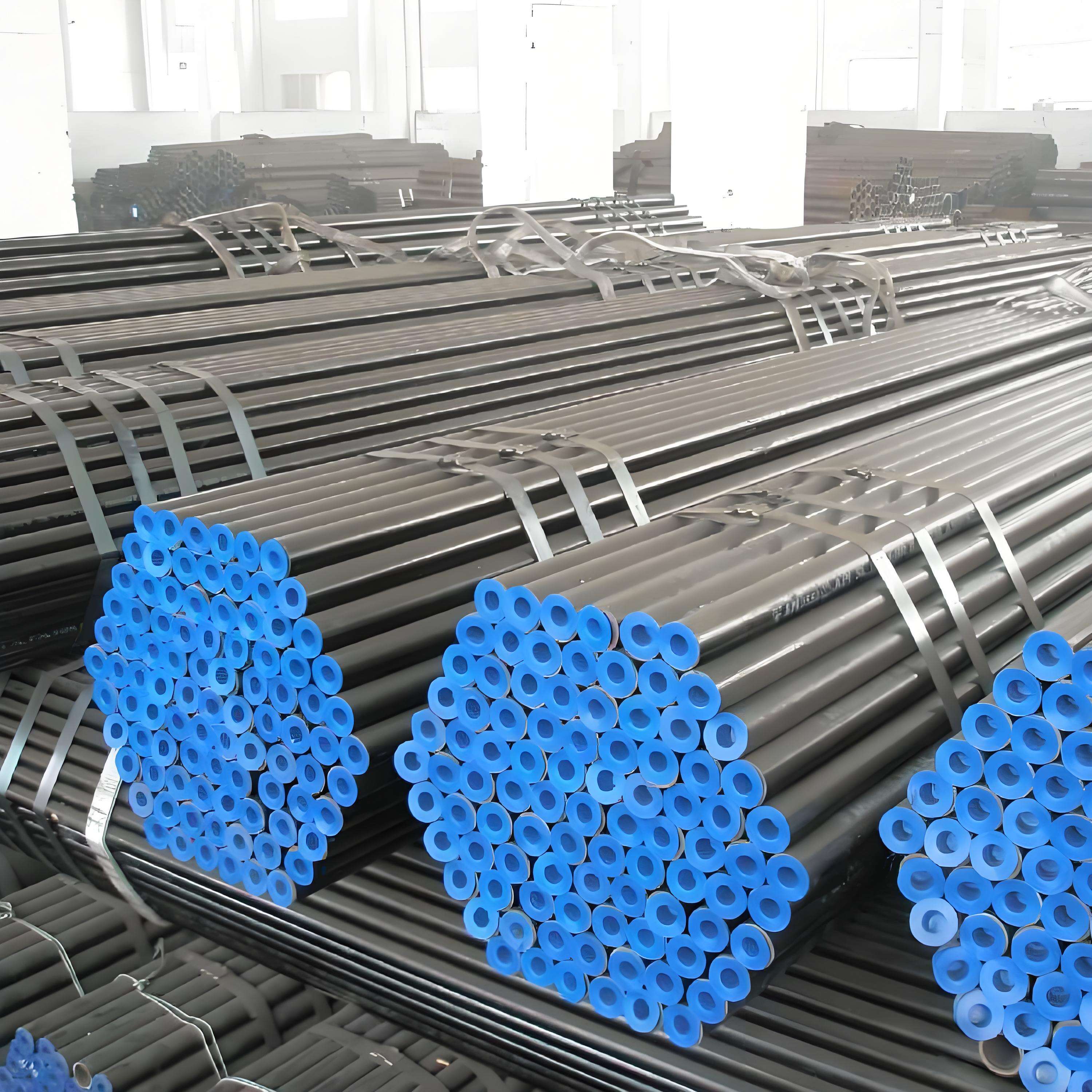

seamless tube suppliers

Seamless tube suppliers play a crucial role in providing high-quality, continuous metal tubing solutions for various industrial applications. These suppliers specialize in manufacturing tubes without any welding seams, ensuring superior structural integrity and performance. The production process involves sophisticated technology that transforms solid metal billets into hollow tubes through hot or cold working methods. Modern seamless tube suppliers utilize advanced manufacturing techniques, including rotary piercing, pilgering, and cold drawing, to create tubes with precise dimensions and exceptional mechanical properties. These suppliers offer an extensive range of materials, including carbon steel, stainless steel, alloy steel, and non-ferrous metals, catering to diverse industry requirements. The tubes they produce are essential in critical applications such as oil and gas transportation, chemical processing, power generation, automotive manufacturing, and construction. Quality control measures, including ultrasonic testing, hydrostatic testing, and dimensional verification, ensure that each tube meets strict industry standards and specifications. Furthermore, leading suppliers maintain comprehensive inventory management systems and global distribution networks to ensure timely delivery and customer satisfaction.