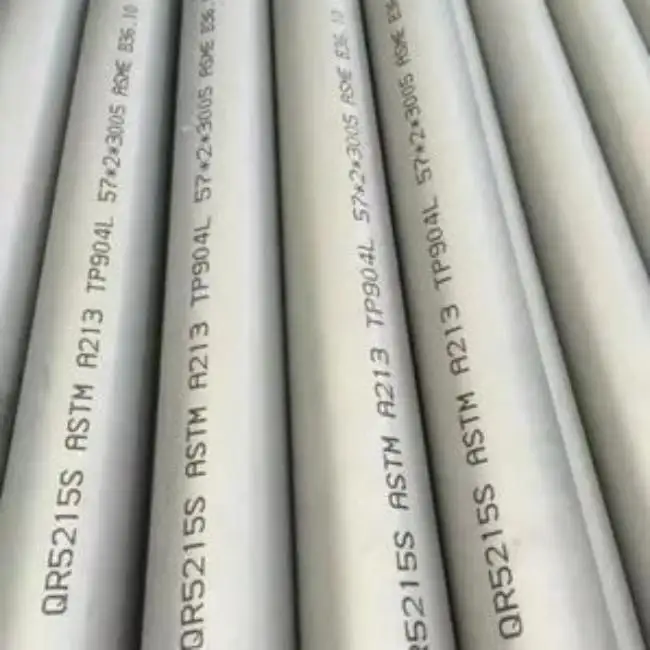

stainless seamless tubing

Stainless seamless tubing represents a critical component in modern industrial applications, characterized by its continuous, weld-free construction that ensures optimal structural integrity and performance. These tubes are manufactured through advanced processes that involve hot extrusion or cold drawing of solid billets, resulting in a uniform, seamless structure that maintains consistent mechanical properties throughout its length. The absence of welded joints eliminates potential weak points and reduces the risk of material failure under stress. These tubes excel in applications requiring high pressure resistance, corrosion resistance, and temperature tolerance. They are widely utilized in industries such as chemical processing, oil and gas transportation, pharmaceutical manufacturing, and nuclear power generation. The seamless construction ensures superior pressure containment capabilities while maintaining excellent resistance to various forms of corrosion, making them ideal for transporting aggressive media. The tubes' smooth interior surface promotes optimal flow characteristics and minimizes the risk of contamination, particularly crucial in sanitary applications. Their versatility extends to both high-temperature and cryogenic applications, supported by their exceptional mechanical properties and material uniformity.