seamless pipes and tubes

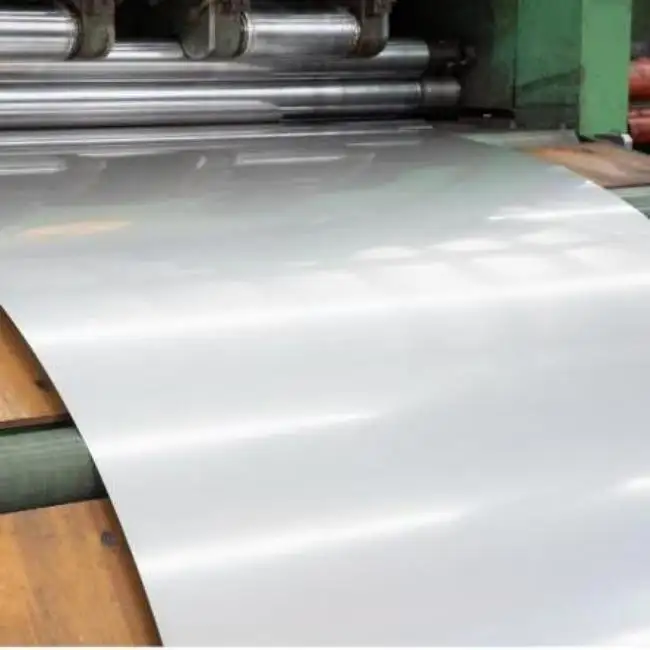

Seamless pipes and tubes represent a pinnacle achievement in metallurgical engineering, manufactured through a sophisticated process that eliminates the need for welded seams. These critical components are produced by hot forming solid billets into hollow cylinders, resulting in a uniform, continuous structure that maintains consistent strength throughout. The manufacturing process involves advanced techniques such as rotary piercing, pilgering, or extrusion, ensuring superior mechanical properties and structural integrity. These pipes and tubes find extensive applications across various industries, from oil and gas transportation to power generation and chemical processing. Their seamless construction makes them particularly suitable for high-pressure and high-temperature applications where traditional welded pipes might fail. The absence of welded joints significantly reduces the risk of structural weak points and potential failure zones, making them ideal for critical operations where safety and reliability are paramount. Modern seamless pipes and tubes are available in various materials, including carbon steel, stainless steel, and specialized alloys, each designed to meet specific operational requirements and environmental conditions. The dimensional accuracy and surface finish achieved in seamless pipe production contribute to improved flow characteristics and reduced maintenance requirements.