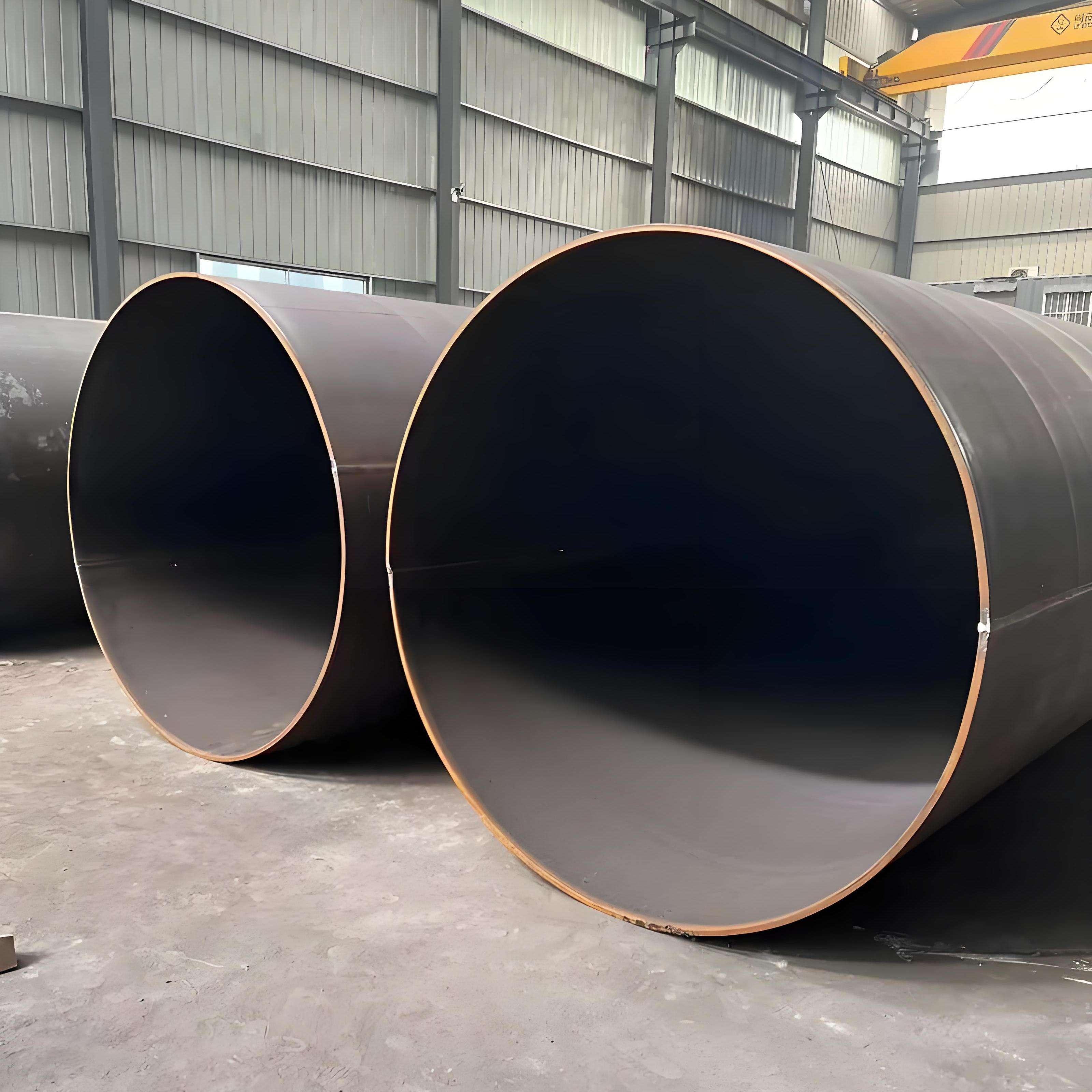

seamless pipes & tubes

Seamless pipes and tubes represent a pinnacle of engineering excellence in fluid transportation systems. These cylindrical structures are manufactured through an innovative process that eliminates the need for welding, resulting in a continuous, uniform wall thickness throughout their length. The manufacturing process involves heating a solid billet of metal and piercing it to create a hollow form, which is then precision-rolled to achieve the desired dimensions. This technology ensures superior structural integrity and reliability compared to welded alternatives. Seamless pipes and tubes find extensive applications across various industries, including oil and gas, petrochemical, construction, and manufacturing. Their exceptional pressure-bearing capacity makes them ideal for high-stress environments where safety and reliability are paramount. The absence of welded joints significantly reduces the risk of structural failures and leaks, particularly in applications involving extreme temperatures or corrosive materials. These products are available in various materials, including carbon steel, stainless steel, and alloy steel, offering versatility in meeting specific industry requirements. The dimensional accuracy and superior surface finish of seamless pipes and tubes also contribute to optimal fluid flow characteristics, making them essential components in critical industrial processes.