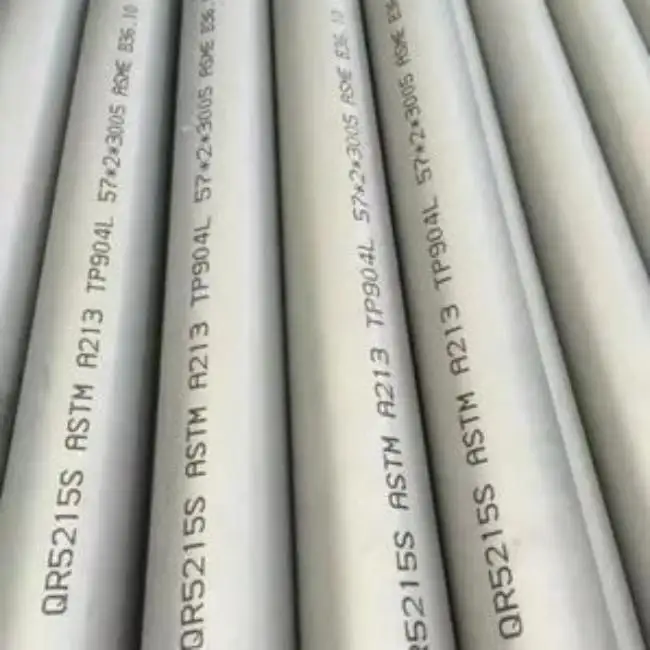

seamless tube pipe

Seamless tube pipes represent a pinnacle of engineering innovation in the piping industry, characterized by their continuous, joint-free construction that ensures superior structural integrity. These pipes are manufactured through an advanced process that eliminates the need for welding seams, resulting in a uniform structure that maintains consistent strength throughout its entire length. The manufacturing process involves heating and shaping solid billets into hollow tubes through specialized mechanical methods, ensuring perfect cylindrical geometry and wall thickness uniformity. These pipes excel in high-pressure applications, offering exceptional resistance to internal and external pressures while maintaining structural stability under varying temperature conditions. The absence of welded joints significantly reduces the risk of structural failures and enhances the pipe's overall reliability. Seamless tubes find extensive applications across various industries, from oil and gas transportation to chemical processing, power generation, and construction. Their superior mechanical properties make them particularly valuable in environments where safety and reliability are paramount, such as in offshore drilling operations, high-pressure boiler systems, and critical fluid transport applications. The pipes' inherent resistance to corrosion and ability to withstand extreme temperatures further extends their utility in demanding industrial settings.