amafitshini ezingasusiwe kakhulu

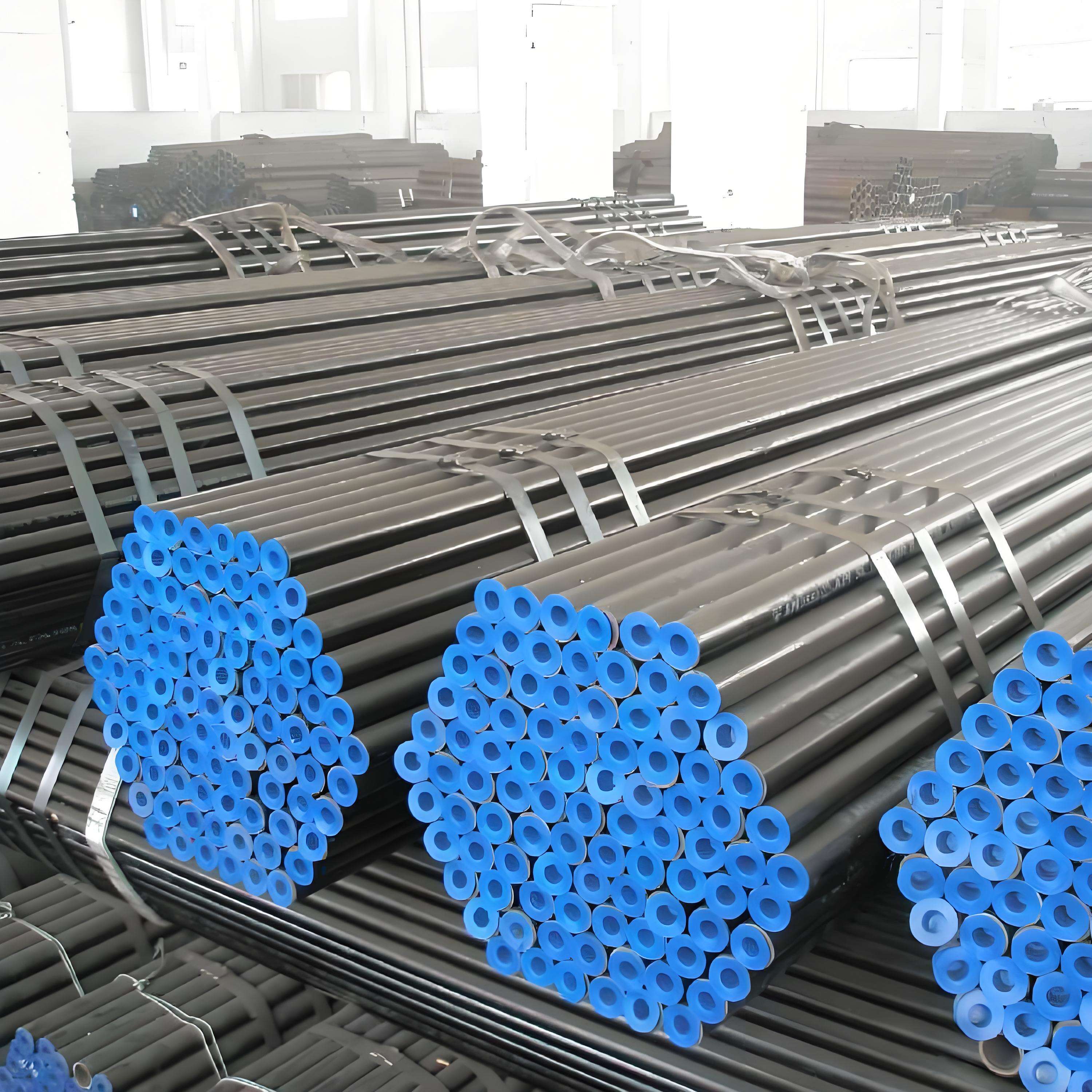

Izinsimbi zokushisela amapayipi zensimbi ziyingxenye ebalulekile ezinhlelweni zesimanje zamapayipi, ezenzelwe ukuhlinzeka ngokuxhumeka okungaguquguquki kanye nokuguqulwa phakathi kwamapayipi. Lezi zici zenziwe ngezinto zensimbi ezisezingeni eliphakeme, eziklanyelwe ngokukhethekile ukumelana nobunzima bezinqubo zokushisela ngenkathi kugcinwa ukuqina kwesakhiwo. Izesekeli ziza ngezici ezihlukahlukene, kuhlanganise nezingalo, ama-tees, ama-reducer, namakepisi, ngalinye lisebenza imisebenzi ethile ekuhlanganisweni kwesistimu yamapayipi. Okuhlukanisa lezi zixhumi ukuthi ziyakwazi ukuhlanganisa izinto ezihlala njalo, ezingavuzi ngokuzisongela, okuqinisekisa ukuthi ziyasebenza isikhathi eside lapho kusetshenziswa izingcindezi eziphakeme namazinga okushisa aphezulu. Inqubo yokukhiqiza ihilela imishini eqondile kanye namasu okubumba, okuholela ekutheni kube nezinto ezihambisana nezindinganiso eziqinile zomkhakha ngokunemba kobukhulu nokwakheka kwezinto. Lezi zixhobo zisetshenziswa kabanzi emikhakheni yezimboni efana ne-oyili negesi, ukucutshungulwa kwamakhemikhali, ukukhiqizwa kukagesi, kanye nezikhungo zokuhlanza amanzi. Umklamo wazo uqukethe izici ezenza kube lula ukuba i-weld ingene kahle futhi ibe namandla okuhlangana, kuyilapho kucatshangelwa izici ezinjengokugeleza komoya nokumelana nengcindezi. Ukuhlukahluka kwezinto zokulungisa amapayipi ezinsimbi ezingashiselwa kuzenza zidingeke kakhulu kuzo zombili izinhlelo ezintsha zokwakha nezokulungisa, lapho ubuqotho nokuphepha kohlelo kuyinto ebaluleke kakhulu.