ipayipha lemsizi engcwele elibhokisiwe

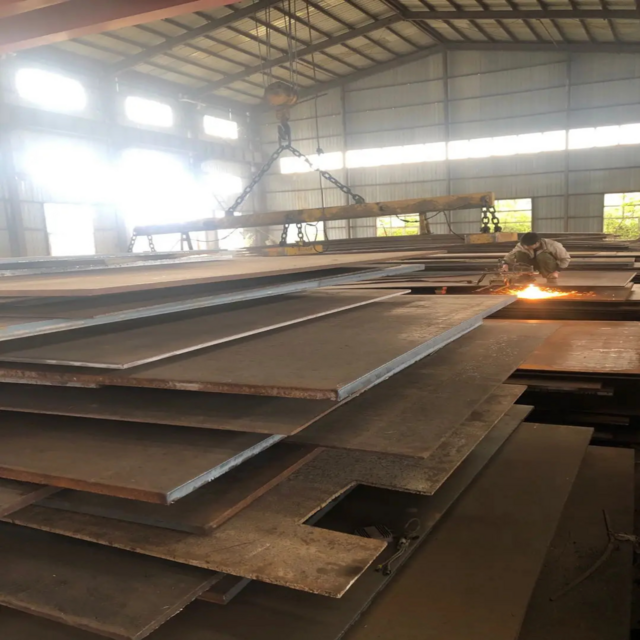

I-pipe yesiCarbon yi-welded steel ifanele ngokubanzi kwi-structure yezilayezo zindlala, ukuhlukanisa nokuthi kuhlula kakhulu. Izipipe zizoshintshwa ngokushicekelwa okukhulu, zibhalwe ngokufakwa amasheethi noma amastrip we-carbon steel ngendawo yokuba ngonyaka okanye ngokuphumuleka okanye ngokushicekelwa. Ukushintshwa, okungakhothekako ukusebenziswa kwamalayithi elecricity nokushintshwa okanye ukusondezela, uzogcinwa ukuthi ubanzi nobungako. Amapipe angaphakathi kwalabo abaningi lomphahla olushintshwa kunye nezi-diameter ezidinga izinambuzo eziningi kunye nemigomo yezindlela ezidingayo. Umbiko wesiCarbon kulesiSithathu esihlanganiswa ngokwesikhatsi esingabangako usizo lokuncane kunye nokuhlukaniswa okungcono, ukuthi amapipe angadingiwe kumazilayezo ezininzi. Zidibana ngokukhulu nekutsi lokulandelayo lokulandelayo, izinambuzo ezivavanyelwe kunye nenkonzo yenkonzo yezindlu. Uphawuli lwemishini lwashintshwa lwashicelwa ngokubanzi ngokushicekelwa okukhulu, luhluke amagama amahhale, kuhluke amaradiographic testing kunye ne-hydrostatic pressure tests, ukuthi zikhona ngokubanzi ngokushicekelwa ngokwesikhashana sesiZwe. Amapipe amashintshwa amacarbon steel azosetshenziswa ngokubanzi kwi-oil kunye ne-gas transportation, i-construction projects, amasistimu ase-water distribution kunye namazilayezo ezingaphezu kwalokhu. Ukuphawuliseko kwazo kuhlanganisiwa ngokuba kunezinye eziphawuliseko ezinhloko, kunye ne-coating systems ezifanelekayo ukuthi zisukele umkhuhlane kunye nezinkonzo zezindlu.