sihlobo sesikhundleniweyo sezansi

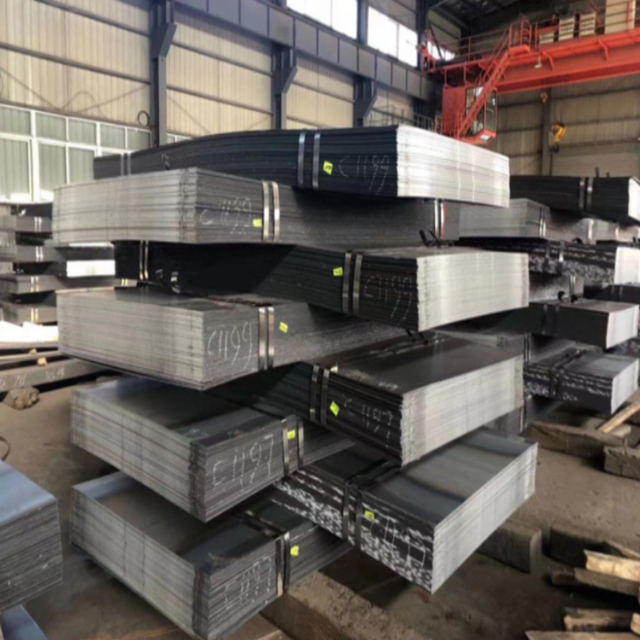

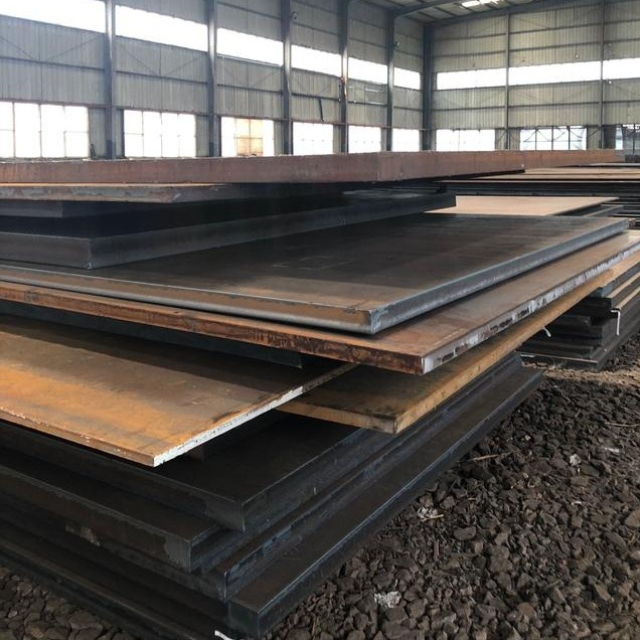

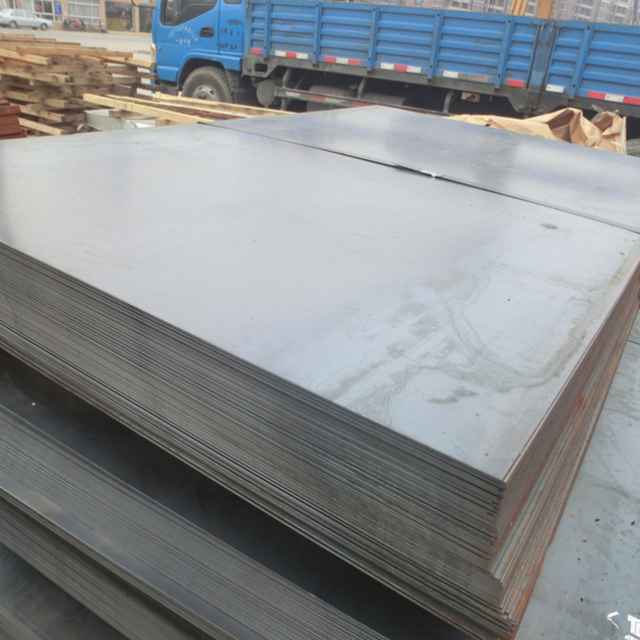

Isigaba sasekhukhene lesi-steel esisethileyo kwi-carbon lisebenzisa uphumaphandle kwesiphumo sokuthiwe ngokulandelana nge-metal manufacturing, lokhu lusunguliwe ngokubheka khona phakathi kwe-surface finish elibonakaleyo kunye ne-tight dimensional tolerances. Lomdlalo uhlale kwenzeleyo lokusebenza ngokuphiwa okukhulu apho isigaba sasekhukhene lesi-steel siyongcwele kakhulu emphephandaba, futhi usetyenziswa ngemvume yezinsuku, ukuba kuhlanganise umoya omphakathi nokuhlola amacala angendlela efanele. Ukuthiwe ngokulandelana ngesigaba sasekhukhene uhlanganisa umsuka wesigaba wesi-steel ngokubheka khona, njengoba ubungakanani, ubungqaleni kunye ne-surface smoothness. Amasigaba amaningi akhawuleza amabatheleni eziqondisiwe phakathi kwe-0.05mm kunye ne-3mm, ukuba zikhankanyiswe kakhulu ezilayini ezidinga amandla amahhhe kunye ne-flatness enhle. Iindlela engcono yokuthiwe ngokulandelana kunye ne-surface finish elinganayo kuhlanganisa isigaba sesi-steel esisunguliwe ngokubheka khona kakhulu kwi-indlela yokugcina imibhalo yobhotela, ukusebenzisa amamekeli kunye ne-components yokuqinisekisa. Umgca wakho wenzelela ukuba kufanele kakhulu kuzama ukwakha amandla amanye amehlo, kwi-indlela ze-furniture yesigaba, i-HVAC systems kunye ne-electrical enclosures kunye ne-precision machinery parts. Ukuthiwe ngokulandelana ngesigaba sasekhukhene uhlanganisa amandla amanye amehlo kunye ne-grain structure okuningi, okungabangela ukwakha umngqithelo okudingekile kunye ne-weldability. Lomdlalo wahlukile ukuba alindele amandla amanye amehlo ukuthiwe ngokulandelana ngesigaba sasekhukhene kunye ne-corrosion resistance xa kusetshenziswa ngokungcono, ukuba kuhlanganise ukuthiwe ngokulandelana ngesigaba sasekhukhene kakhulu kumncedisi kunye ne-aesthetic applications kwi-modern manufacturing.