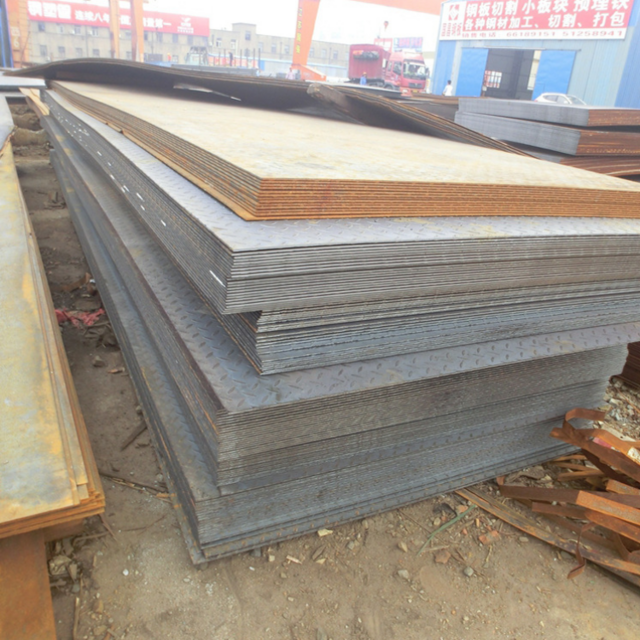

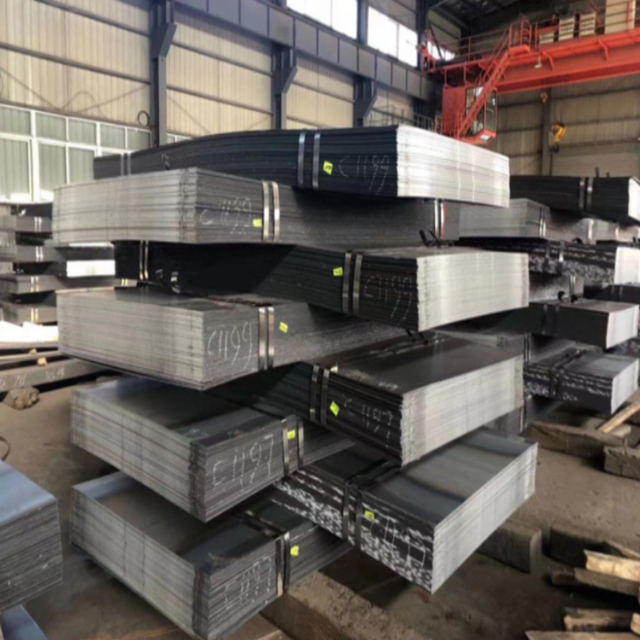

isayidi samabhedheni esincinci

Isigaba sasemthethweni esilow carbon sisho ngokwesentle kanye nokusebenzwa ngokupheleleyo, ifanele yizoqobo zayo ezikhona phakathi kwe-0.05% kunye ne-0.25%. Umhlaba omphumelelo wokuqhathanisa lokhu kuhlala ngenhla kanye nokuthi amaphawu akho ayiphi atholakele, ukuba kuhle kakhulu ukubonisa nokuthola amandla okuphathelene, ukuze kube yindawo yokukhetha elingekayo kumanyano oluninzi lomsebenzi olunxibelekileyo. Isiphumo sokugcina kufaneleke izindlela zokuhlala kanye nokuhlala ngokushesha ukuvumela umkhondo womgca ofanele nokulandelana namandla. Amasigaba aqondiswa ngokukhulu ukusuka nokusetyenziswa, ukuba kuhle ukusetshenziswa nokuba kuhle ukusethelayo. Ukudabula kwezinto eziphumaphi kuhle kakhulu ukuba zisetshenziswa ngamandla ezininzi zomsebenzi futhi azifanele ukuthi zisuke zisuke ukuthi zimahasha imithombo yakhe. Izigaba zesemthethweni esilow carbon zihlala emanzini edluleyo, ukuba zikuphumelele kwiindawo eziningi ezinikezelwe. Zingabhedlisele ukungazixhaswe ngokwesizatu somdlalo olungaphezu kwesintuthuko somdlalo xa zitshonalanga kwezinye izinto, kunye nokuziphatha kakhulu kakhulu ngokuthi zisetyenziswa njengezinto ezahlukene nokuthi ziqhamuka ngokuphathelene. Ukuthi le mhlaba angakho ukuthi alungiselele ngokuncane kanye nokuthi amandla akho akuyiphi akuyiphi, kungavalelwe njengendlela yokugcina nokuthi yinketho yesiphumo sokuthi yinhloso ekubalulekileyo kwiindawo yokugcina nokubhedlisa.