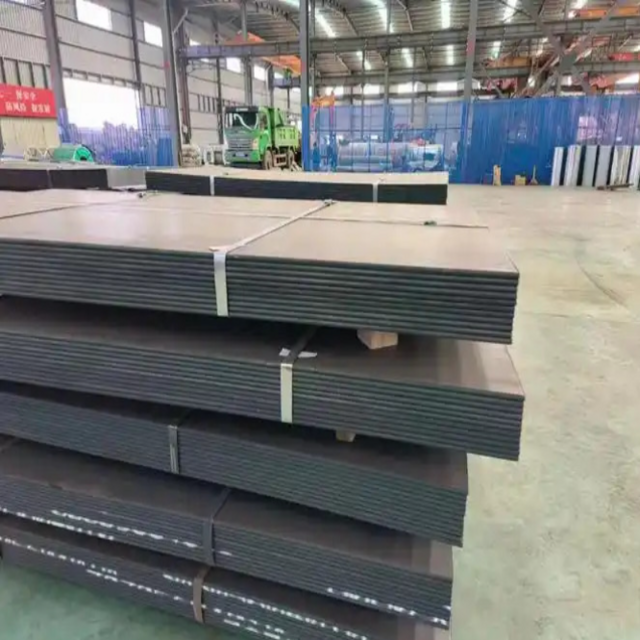

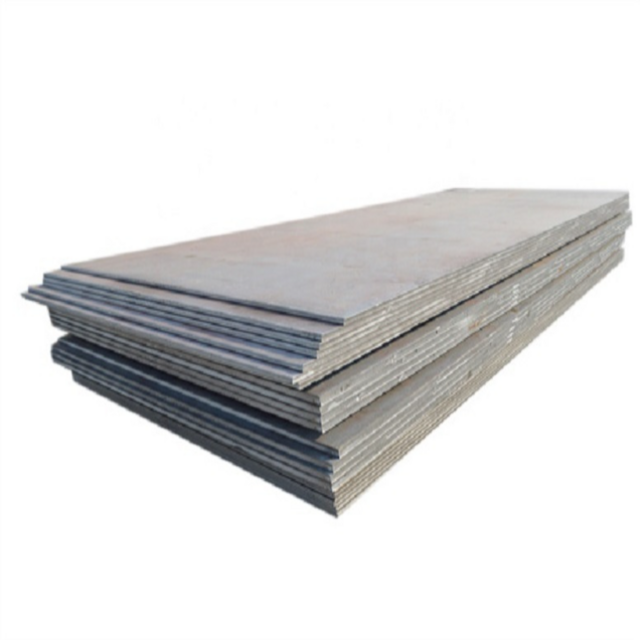

hot rolled carbon steel sheet

Hot rolled carbon steel sheet represents a fundamental material in modern manufacturing and construction industries. This versatile product is created through a high-temperature rolling process, typically above 1,700°F, where steel is heated and passed through massive rollers to achieve the desired thickness and shape. The process results in a material that exhibits excellent formability, weldability, and cost-effectiveness. These sheets are characterized by their slightly rough surface finish and slight variations in thickness tolerance, which are perfectly suitable for many industrial applications. The material's chemical composition primarily consists of iron and carbon, with carbon content typically ranging from 0.05% to 0.25%, providing an optimal balance of strength and workability. The manufacturing process ensures uniform mechanical properties throughout the sheet, making it ideal for applications requiring consistent performance. Hot rolled carbon steel sheets are extensively used in automotive components, construction materials, industrial equipment, and various structural applications where high strength and durability are essential. The material's versatility is demonstrated in its ability to be further processed through additional treatment methods, including cold rolling, galvanizing, or painting, to enhance specific properties for particular applications.