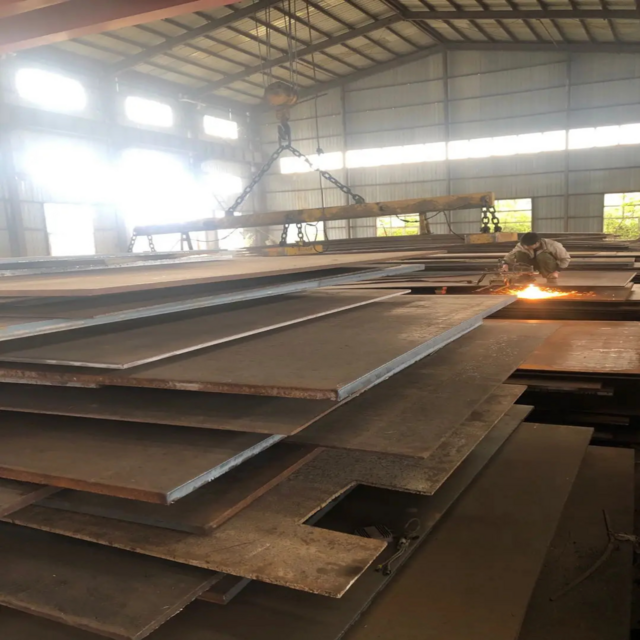

carbon steel sheet price

Carbon steel sheet price represents a crucial factor in various industrial and construction applications, reflecting the market dynamics of this versatile material. Carbon steel sheets, manufactured through precise rolling processes, offer an optimal balance of strength, durability, and cost-effectiveness. The pricing structure typically varies based on several factors, including thickness specifications, grade quality, surface treatment, and market demand. Current market trends show fluctuations influenced by raw material costs, particularly iron ore and coal prices, as well as global supply chain conditions. These sheets are fundamental components in automotive manufacturing, construction projects, and industrial equipment fabrication, making their pricing a key consideration for procurement managers and project planners. The material's carbon content, ranging from low to high percentages, directly impacts both performance characteristics and price points. Modern manufacturing techniques have enabled producers to maintain competitive pricing while ensuring consistent quality standards, meeting various international specifications and certifications. The market also reflects regional variations, with prices affected by local production capacity, transportation costs, and trade policies. Understanding these pricing dynamics is essential for businesses to make informed procurement decisions and maintain cost-effective operations.