carbon steel pipe grades

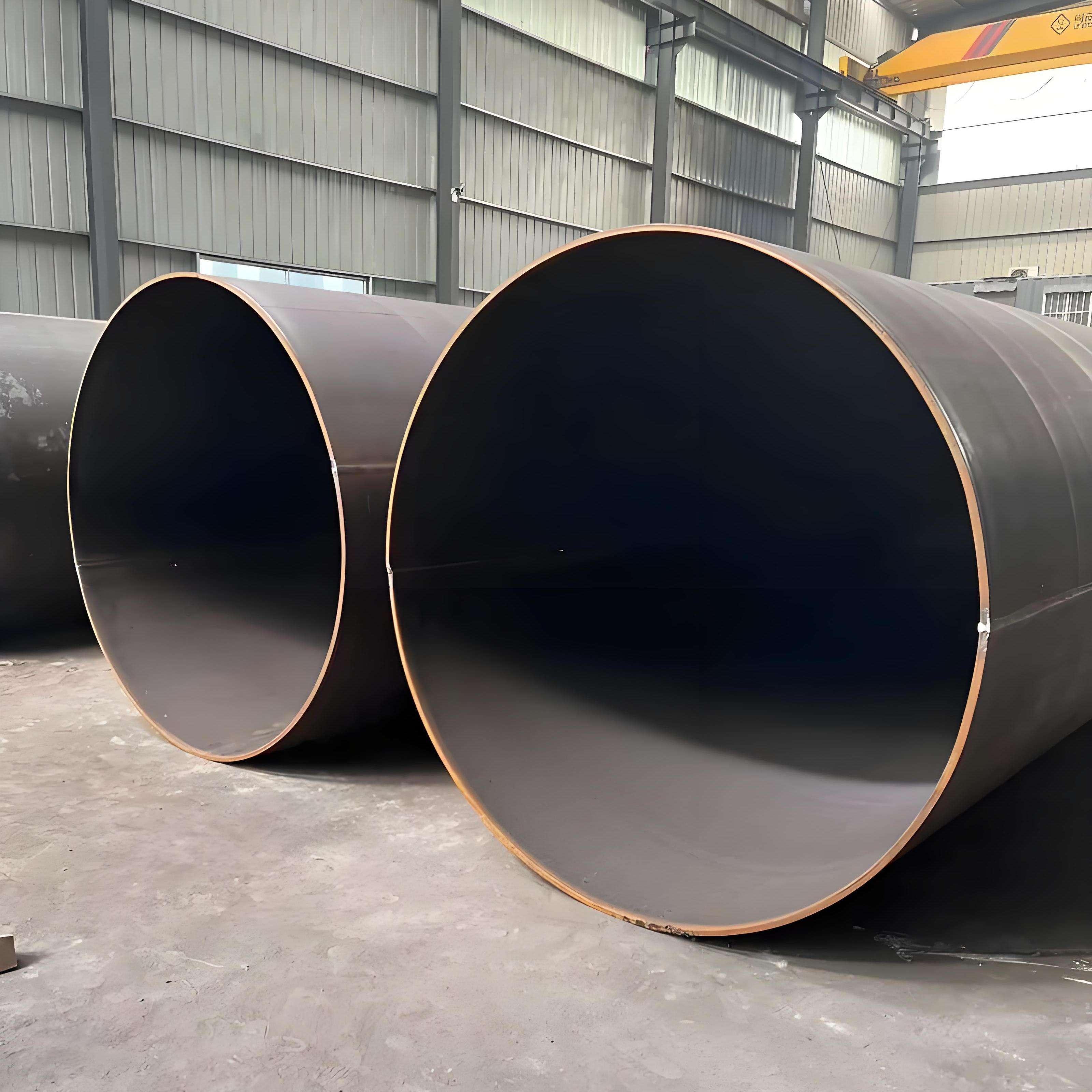

Carbon steel pipe grades represent a crucial classification system that defines the mechanical and chemical properties of steel pipes used across various industries. These grades, typically denoted by standards like ASTM A53, A106, and API 5L, determine the pipe's strength, durability, and performance characteristics. The classification system primarily considers the carbon content, which ranges from low carbon (0.05-0.30%) to high carbon (0.30-1.70%), significantly influencing the pipe's mechanical properties. Carbon steel pipes are manufactured through seamless or welded processes, offering different advantages depending on the application requirements. These pipes excel in high-pressure and high-temperature applications, making them ideal for oil and gas transportation, construction, and industrial processing. The standardization of carbon steel pipe grades ensures consistency in quality and performance, enabling engineers and contractors to select the most appropriate grade for their specific needs. Modern manufacturing techniques have enhanced the precision of grade specifications, allowing for tighter tolerances and improved reliability in critical applications. The grading system also considers factors such as yield strength, tensile strength, and chemical composition, providing a comprehensive framework for material selection.