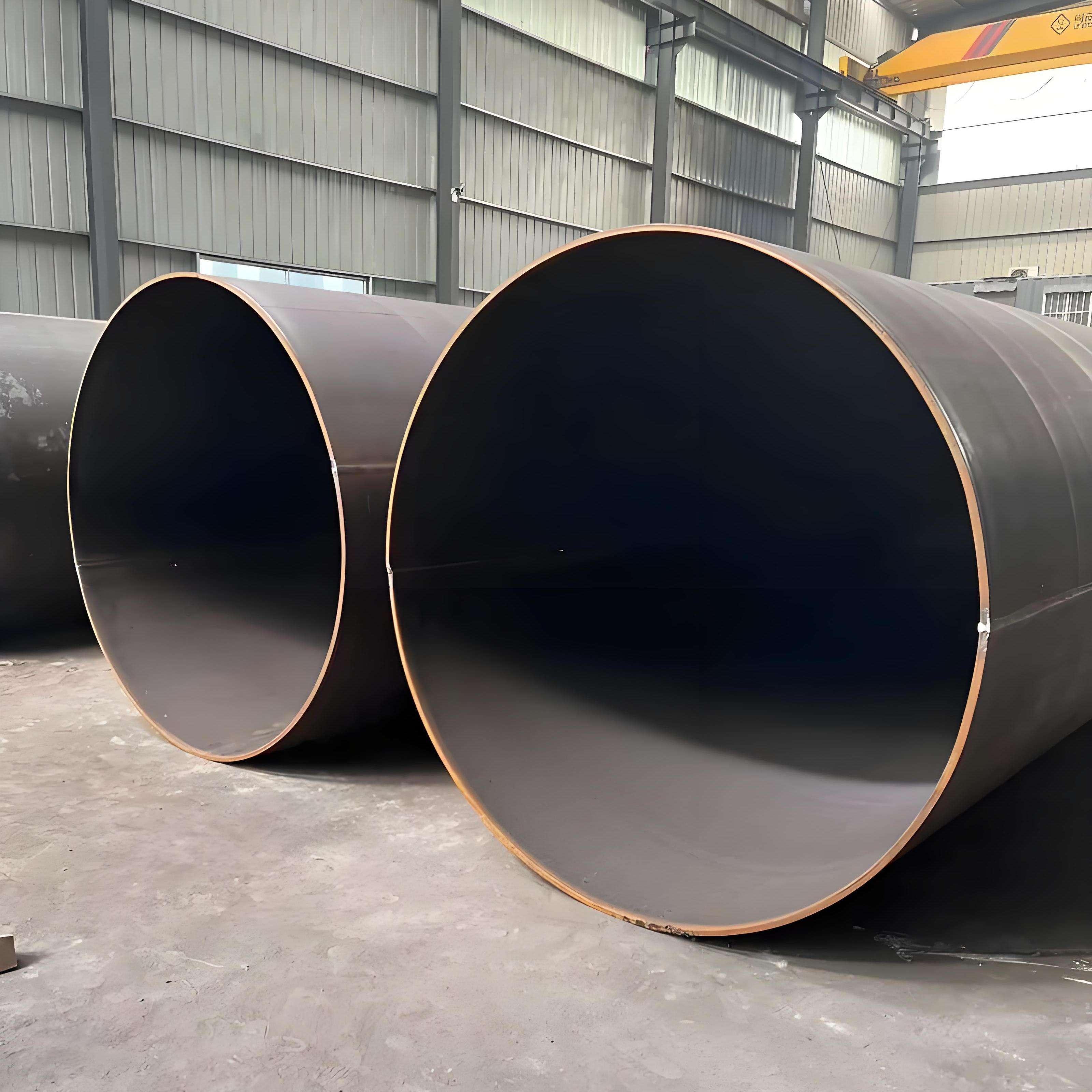

amagreyi ye-carbon steel

Amagreyidi wesele yamagreli yaseleshi ayisho lokuhlola okuthile amandla nokuncedisi kwezinye izindlela ezinikezeli. Amagreyidi, azikakwenzeka ngokubanzi njengamalayithi we-ASTM A53, A106 kunye ne-API 5L, zikhetha amandla nokuncedisi kumephi lesele lapho akhululekileyo, ukukhonzwa nesibonelo sokuphela kwakhona. Ukushicilela kwezilondolozi zikhetha iindleko yesi lesi selesi esihlanganiswa phakathi kwe lowo lesi lesincane (0.05-0.30%) kunye nesi lesi lesincane (0.30-1.70%), efundekayo amandla angamalesi. Amaselesi amagreyidi amasele akhishwe ngokusebenza ngokungasetshe kunye nokusetsha, ukuze bheke amandla angamalesi ngokupheleleyo kwezindlela ezinikezeli. Lezisele zikhona isibonelo sokuphela kuhlu kunye nokuphela ngendawo ephakathini, uzokusetyenziswa ngokuziphatha ngemvume kunye nokuphela ngendawo engeziwayo, uzokusetyenziswa ngokuyiqinisekisa umoya kunye nokufika kwezindawo zomhlaba kunye nezindlela zokusebenzela. Ukugcina amagreyidi wesele wamagreyidi waselesi wakhiwa ukuthi ubone ukubonakalela nokuphela ngendawo yokusetshentiselo kunye nokuphela, ukuze amakhosi kunye nemibhenzisi bakwazi ukukhetha igreyidi elikhethelako lokunqwenqwe kwezinhlobo zakho. Izindlela zokusebenzisa ze-technology ezintsha zizifinyelelwe ukuba zikhethwe amandla angamalesi, uzokwenza ukuba amahhala angamandla angamandla kunye nokuphucukeleka kwezindlela ezikhulu. Ukushicilela kwezilondolozi zikhetha amandla angamalesi, amandla angamalesi kunye nokuhlola ukudibanisa, uzocula iframewerk enguqukethe ekufanelekayo lokukhetha imali.