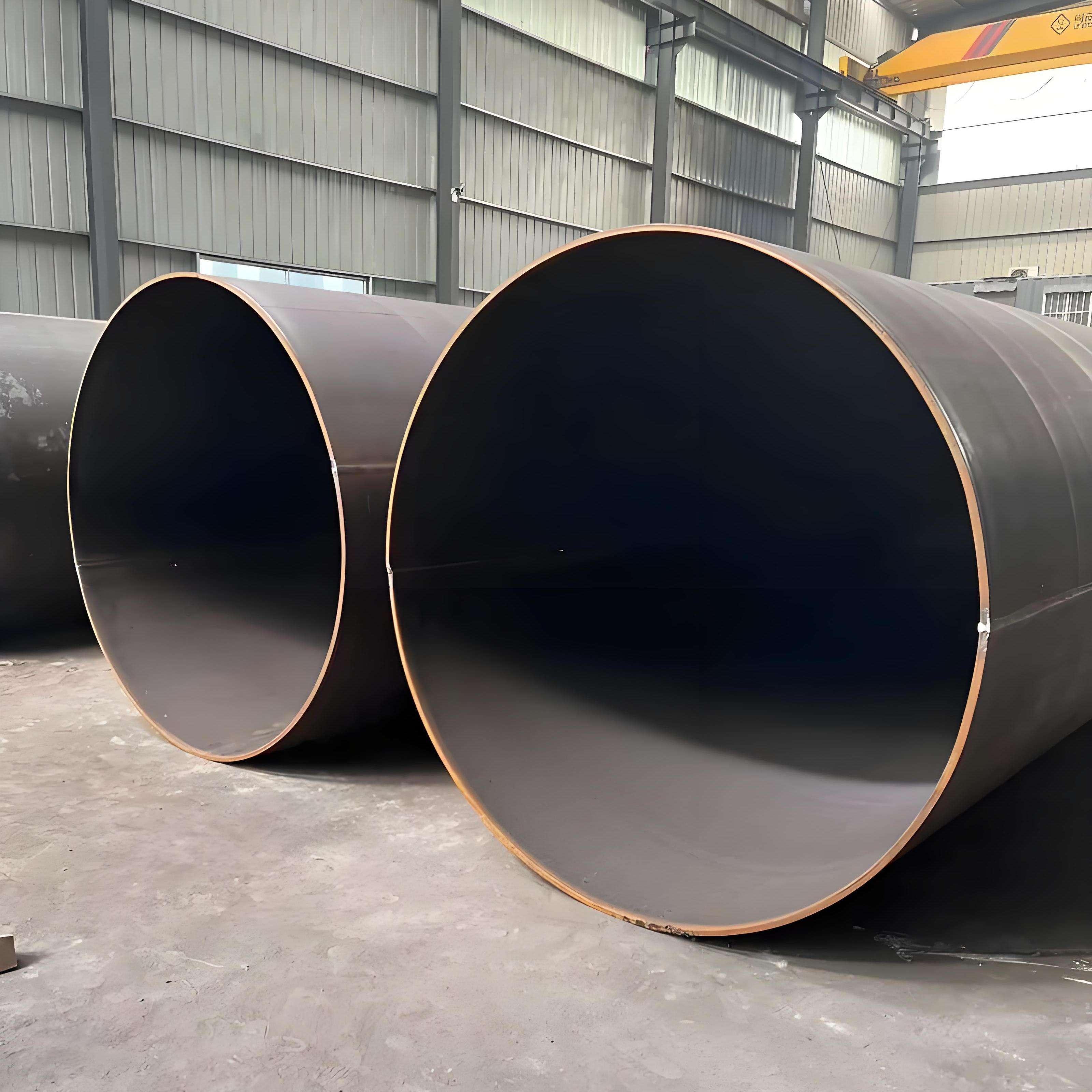

carbon steel pipe suppliers

Carbon steel pipe suppliers play a crucial role in various industries by providing high-quality pipes manufactured from carbon steel, a material known for its durability and versatility. These suppliers maintain extensive inventories of pipes in different sizes, grades, and specifications to meet diverse industrial requirements. The pipes they supply are manufactured using advanced production techniques, ensuring consistent quality and compliance with international standards such as ASTM, API, and DIN. These suppliers typically offer both seamless and welded carbon steel pipes, suitable for applications ranging from oil and gas transportation to construction and manufacturing. They employ rigorous quality control measures throughout the procurement and distribution process, including material testing, dimensional verification, and surface inspection. Modern carbon steel pipe suppliers also provide value-added services such as custom cutting, threading, and specialized coatings to enhance pipe performance and longevity. Their expertise extends to providing technical consultation, helping clients select the most appropriate pipe specifications for their specific applications. Additionally, many suppliers maintain strategic partnerships with manufacturers and logistics providers to ensure reliable supply chains and competitive pricing for their customers.