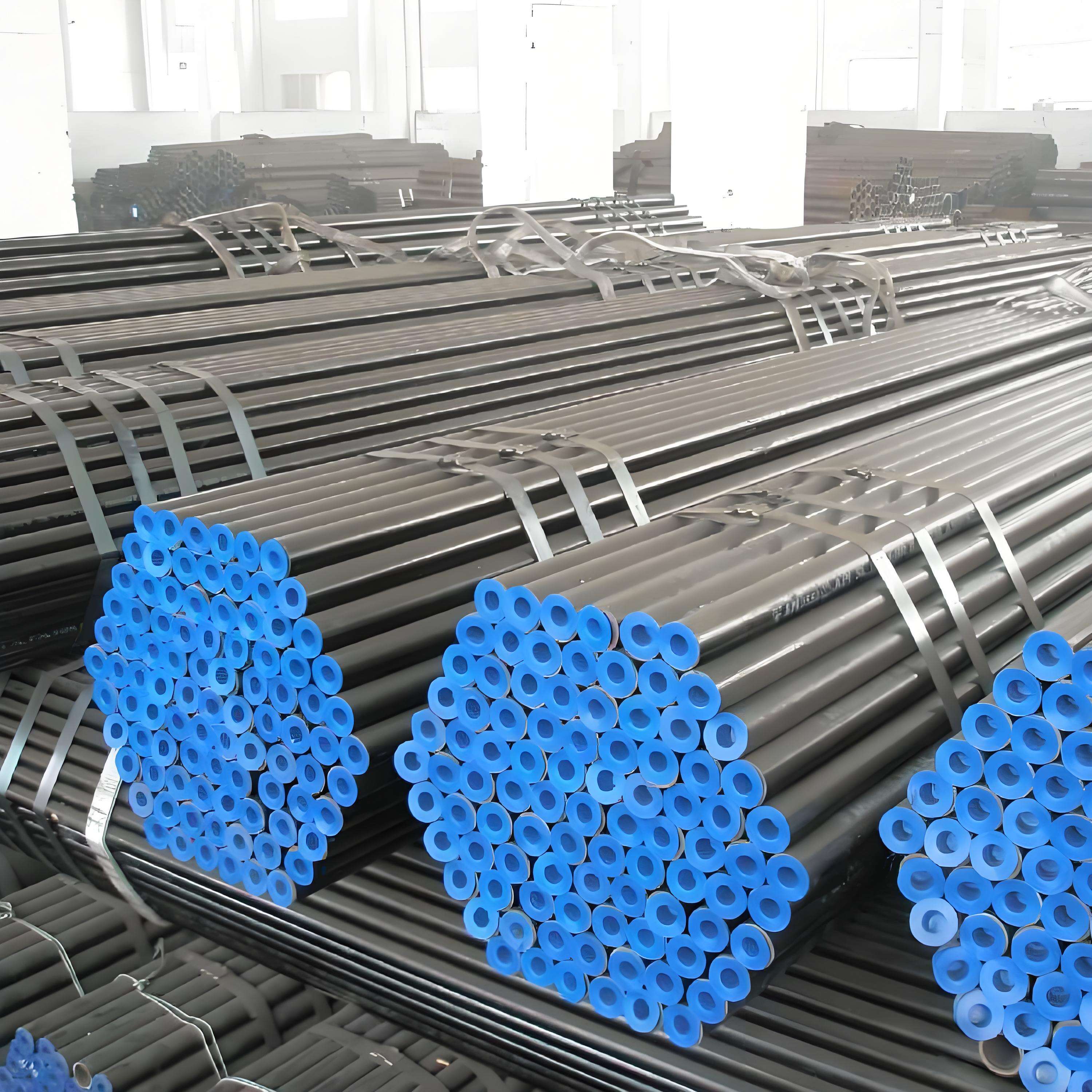

carbon steel pipe cost

Carbon steel pipe cost represents a crucial consideration in industrial and construction projects, encompassing various factors that influence the final pricing. These pipes, manufactured from steel with carbon content ranging from 0.05% to 2.1%, offer exceptional strength, durability, and versatility. The cost structure typically includes raw material expenses, manufacturing processes, diameter specifications, wall thickness, and length requirements. Market conditions, including steel prices and supply chain dynamics, significantly impact the overall cost. Quality grades, ranging from low to high carbon content, affect both performance characteristics and pricing. The pipes find extensive applications in oil and gas transportation, construction, manufacturing, and utilities infrastructure. Transportation costs, bulk ordering quantities, and regional availability also play vital roles in determining the final price point. Modern manufacturing techniques and quality control measures ensure consistent product quality while optimizing production costs. Suppliers often provide various pricing tiers based on order volume and long-term purchase agreements. Understanding these cost components helps buyers make informed decisions aligned with their project requirements and budget constraints.