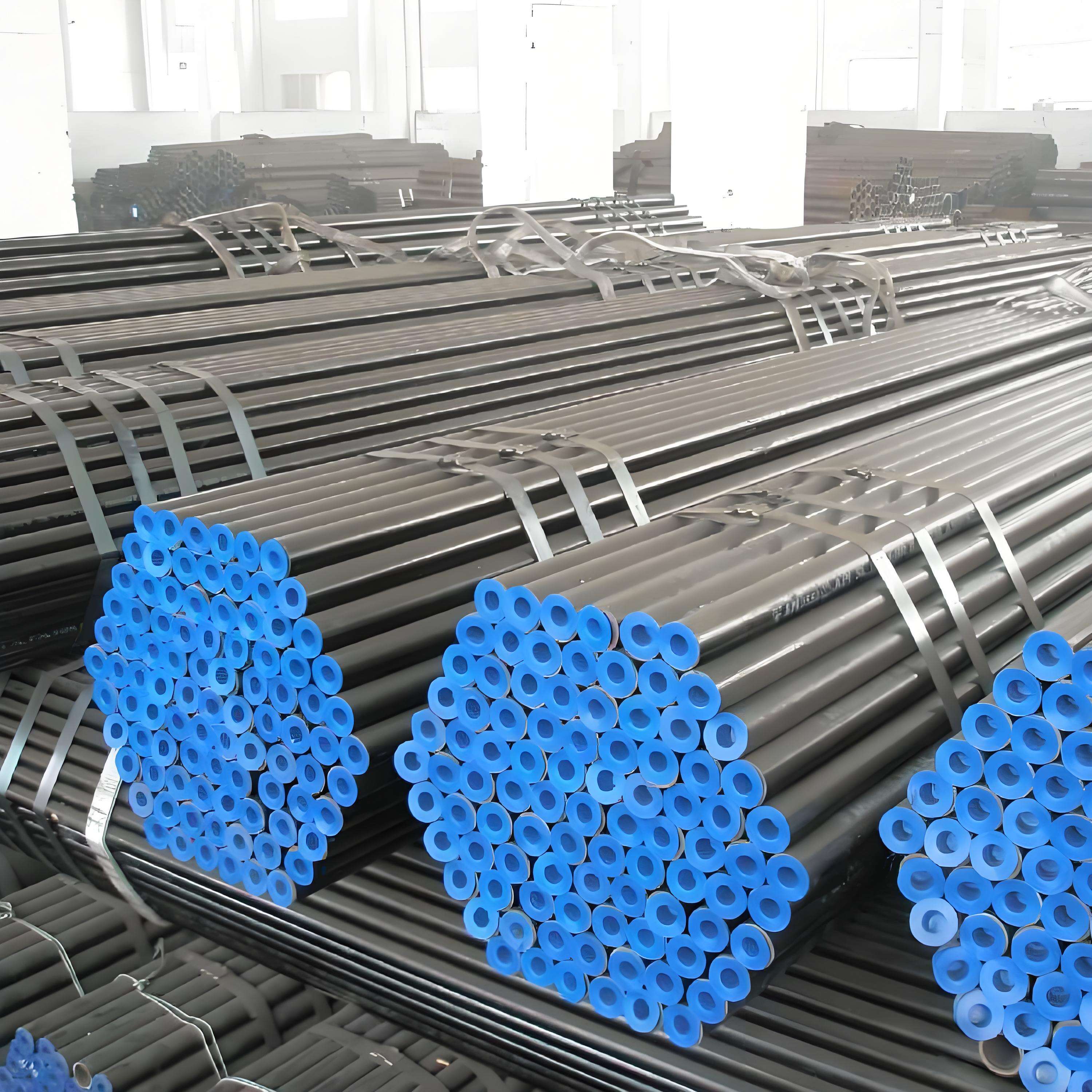

ukuphuma kwe-carbon steel pipe

Iphethelo lestele yomgca wesele yikhutshwa ngokubanzi kwiimpahla zokusebenza nokusukela, ukulingana nesi simulani esizenzekelayo ezifinyeleleyo umdingezo. Lezintaba zinabeke izindlela emfunyeneyo, umbuyile kunye nekhombisano, futhi baye amandla okungakho, umbuyile kunye nekhombisano. Umthengiso wephethelo lufuneka luhlale kwezinto ezithathelayo lokuncedisiyo loluhlu lwamathuluzi, imisebenzi yokugcina, i-specifications yediameter, umbhodwana wesigqibo, kunye nemigomo yesihlanu. Iimiphumela zemakhetha, abahlukeneyo babesentisisi besi sekelo kunye nezinto zokuthatha izinkumbulo, zikhuzekele khona isiqephu sesingabangako. Izigradi zeqhutywa, ezidinga ukuthi ubuciko obuchaze inani lesicelo kunye nokuphumelela, azange akhokhe amandla nokuphumelela kunye nezinga leziphethelo. Amantuba afuneka asebenze kakhulu kwindawo ye-oil kunye yenhliziyo, ukusukela, ukugcina, kunye nokuthatha izindawo eziphumulekileyo. Iphethelo leshintsho, amanani athuliweyo kunye nenkulunkulu yokushintsha kuzo zikhokha izinsuku ezinhloko zokuthola iphethelo elibonakalayo. Izimo ezincane zasekuhlala kanye nokuhlola ukuthi kuhloniphe umthengiso omncane ngokuthi kuhloniphe umthengiso omncane ngokuthi kuhloniphe umthengiso omncane ngokuthi kuhloniphe umthengiso omncane ngokuthi kuhloniphe umthengiso omncane ngokuthi kuhloniphe umthengiso omncane.