amathili amahlukene wezintsha amahlukwe nokulindwa

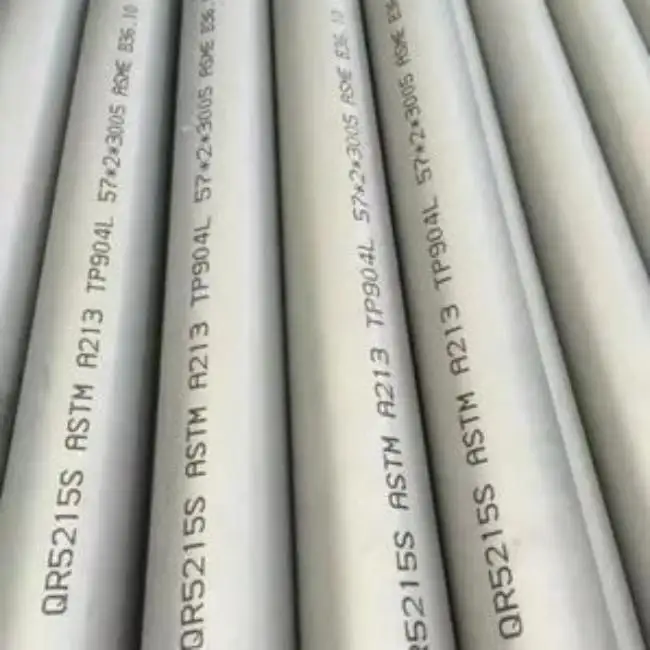

I-tubing ye-stainless steel elihlukile kanye ne-drawn iyiphrofethi yomphathiso wesibayeni ohlonipheke ekuxheleni lokusebenza nge-welding kunye nokuhlelekile kokudrawa. Lolu hloko luhlukile lufuneka kuqala ngemphoyiso wesistrip esesintsha stainless steel esifakwe kwaye sihlukise kanye sikhwedise ngokulula, phakathi komoya, kulesi sikhatsi sithiwa isimo sokudrawa esisindisa amandla angaphandle kanye nokuphucukeleka kwe-surface finish. Umphathisi wesibayeni usure ka-kahle ukusukela imibhalo engaphezulu, uphawu olungaphansi lwesikhephe, kunye namandla amandla olungaphansi. Amatubi akho amahlukile ngendlela yokugcina, amarholwane amahluhlu, kunye nokudibanisana okuphumeleyo nge-diameter, ezinyezi zonke izindlela ezidingekayo ukuze zisebenze ngokuthi zilungileyo kunye nokuzenzekelayo. Umpopho woku-hlukisa ubuyabuyele kakhulu ngemuva kokudrawa, kwaye asikhangati futhi kakhulu kumthetho wesintsha. Ukudrawa kusho ukusukela imibhalo engaphezulu, kusho amandla kunye nokuphucukeleka kwe-surface finish. Lezi zinto zingazama ukuba i-tubing yesintsha stainless steel elihlukile kunye ne-drawn liyinkantolo engeyiyo lokusebenza ngokuthi zizidingekayo kwi-industri yase-aerospace, yase-automotive, yamadivayesi we-medical kunye ne-chemical processing, apho umkhondo kunye nokuphucukeleka kwesintsha kuhluke kakhulu. Ukuphucuka kwe-tubing kunye nokuphucukeleka kwe-mechanical properties kusure ukusukela indlela eyidingekayo kwi-indlela ezincedisi.