amafitshani wezipayiphi ezindilingwe kwezintathu

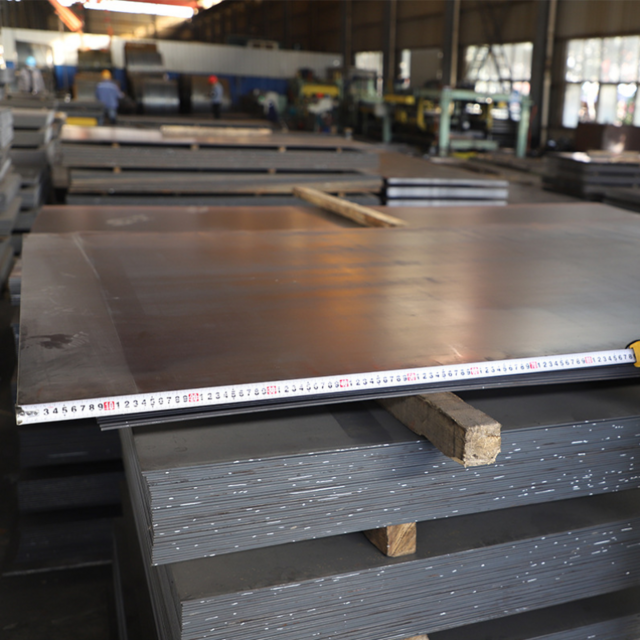

Izimvano zokuhlanganisa izilondolozi zesiStainless Steel zikhona kwiqhutywa lokusebenza lama-industri, ezikhethwe ukuthi zihlangele amandla nokuhlola umoya wamashonaleni ngenxa yokuqinisekiswa kokubonisa ubuvelulekileyo bokushesha. Izimvano ezinhloko zikhiqizwe ezingcinane zingavunyelwe ngemali oshumi olungaphakathi lokusiStainless Steel, uzokusetyenziswa okukhulu kuhlukezo lokulawula nokusenzeniso kumazibuko eziphambili. Izimvano zisetyenziswa ngokupheleleni kwezinto ezindala zokuhlanganisa amandla, ezikhetha izixhumanisi zikhona ngendlela engasithuthi, uzokusihlukanisa ukuhlolwa nokuvumelanisa okungasesidumo. Zikhona ngokwesinye esincinci lokunciphako lokuhlola, phakathi kwemakhono, amathree, amareducer, namacross, lokuzoba abantu ababangako babangene nezilondolozi ezifanekayo. Umsebenzi wokugcina kufumanekisa imigomo emiphi-mpho yokusetshenziswa nokuhlola ukuba kungenani indlela yokuhlola nokuhlola. Izimvano zikhona kakhulu kuma-industri apho isenzo seshonaleni noma usenzo lwesintu sihlukezo, njengemisebizo wesitshalo, upharamasiweyo, noma uchemical processing. IsiStainless Steel sokugcina kusetshenziswa ukuthi akhulumele kuwothando omkhulu, i-pressure variations, kunye nomagama omkhulu, ngakho ke amajongi angesetshenziswa ngokupheleleni kwezinto esiqinisekise kusukela. Izimvano zeStainless Steel ezincinci zisetshenziswa ngokuba zikhona amahhadi alandelule apha kuzobaluleka ukusuka kwezinye izinto nokusetshenziswa kwegumbi.