umphoyiso wesele wesikhombisa esilula amahole

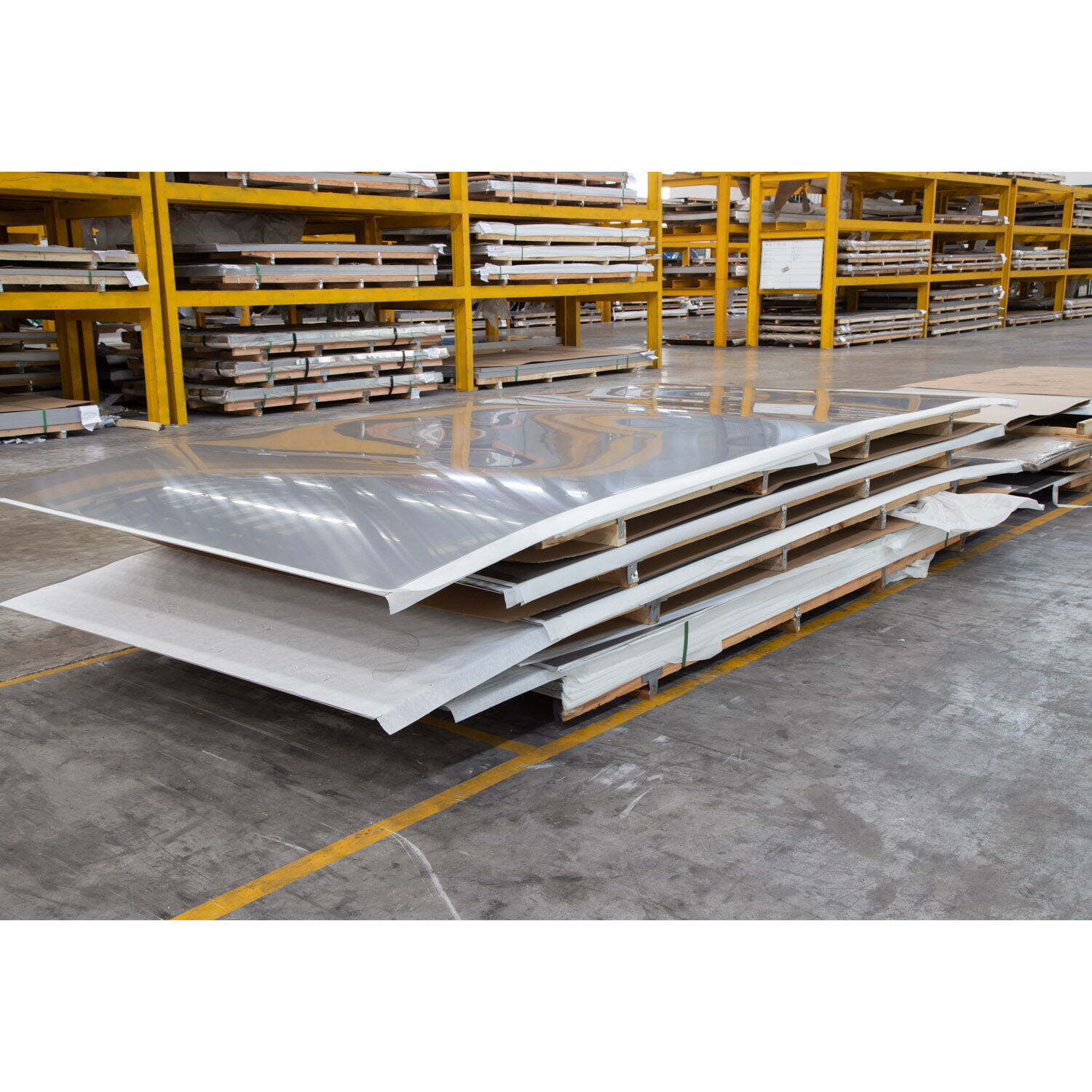

Iphetha lemsizi wesintu enhlangene ngezinye eziqoqwe kusetshenziswa ngokuphakamisayo nokuthi kusenziwa kakhulu kwiindawo zokusebenza. Amaphetha akhethwe ngokusemiswa kwezindlela ezidingekayo, kunye nezinye izindlela ezinomsindo. Izinyezi zinakwazi ukubuyiselwa ngasayizi, uphawu kunye nokusetyenziswa ukuvumela amanani okufanele. Umthombo wokuqala, usetshenziswa ngokungcono emagca yemsizi wesintu, njengemagca 304 okanye 316, ikwenza ukuba kunesiphumo esikhonzayo lokugcwalisa phakathi kwesibhedlela, imigomo yesiphelo sokudala, kunye nokukhathalika kwezinto zokusetyenziswa. Ukusetyenziswa okulandelayo kwenziwa ngokuhlola ngokukhona, ukuze kube kuhluke ukufinyelela, ukuvula amadonda kunye nokuphatha amathambo ngendlela enenhloko yokuthi. Amaphetha akhethwe ngokubanzi kwindawo ezininzi ezisebenzisa amasiko, futhi kuhluke ukuthi zisetshenziswa ngokungcono kwindawo yokulandelana nokuthi zihlabelele kakhulu kwindawo yokusebenzela kanye nokuthi zihlabelele kuzama ukusuka nokufika. Ukusetshenziswa kwenziwa ngokuhlola ngokukhona, njengokusebenzisa i-CNC punching, laser cutting, okanye water jet cutting ukuvumela amaphetha angahlala ngokungcono ngendlela yakho yokusetshenziswa. Amaphetha akhethwe ngokungcono ngokuhlola ngokukhona nokuhlola ngokungcono ukuvumela amanani okufanele.