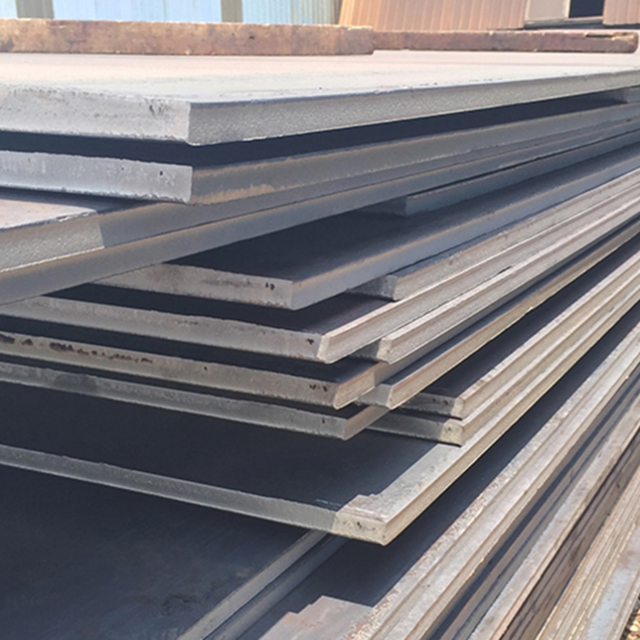

isidingo esilayishiwe ngomgqatelo we-stainless steel

I-coil yesi-stainless steel esihlangan ngokushesha kufanelelwa ngokuthi yisebenzise uphindo oluphephile olungena nge- metallic lwenziwe ngendlela eyahlukene yoku-shesha, apho i-stainless steel iyahlanganiswa phakathi kwe-rollers ngomoya omphakathi. Lendlela ifumanisa isiphumo sasendawo esikhulu, uhlu lwamandla olucacile kakhulu, kunye nomsebenzi wesizathu esibonakale kakhulu. Umthombo ubhekisele ukusuka kuhambisana ngenkinga lokuncedisi lokuhlola, uzama ukwaphindela imigomo yethu ngazo ngemvume wokugcina. Lezi coil zinikwa amagreyde eziningi, amadepthi, kunye ne-widths ukuze zifule amanani ahlukanayo okusebenza. Uphindo lokushesha lungenisa umthombo wamandla ngokubonakala nokuba kuhlanganiswa, ungenisa umthombo omncane, ungenisa umthombo olungabafundi kunye nokulula ukusetshenziswa. Isiphumo sasendawo singekho kwi-bright annealed kunye ne-matte, ngokubanzi kumthetho wesicelo. Izindlela zasekhaya zingenisa iziqiniso ezikhulu zokuthi zikhona ngalandelini lokoco, ngekuthi zihlinyelwe ngokuphelele ukuzimisela kunye nokuziphindezela kwe-surface defects. Ukusetyenziswa kwesinye sisophule ukuba kufanelelwa ngokuthi kube ngaphandle kokunquma kunye nokuhlola, kufanelelwa ukuba kufanelelwa ngokuthi kube ngaphandle kokunquma kunye nokuhlola, kufanelelwa ukuba kufanelelwa ngokuthi kube ngaphandle kokunquma kunye nokuhlola, kufanelelwa ukuba kufanelelwa ngokuthi kube ngaphandle kokunquma kunye nokuhlola.