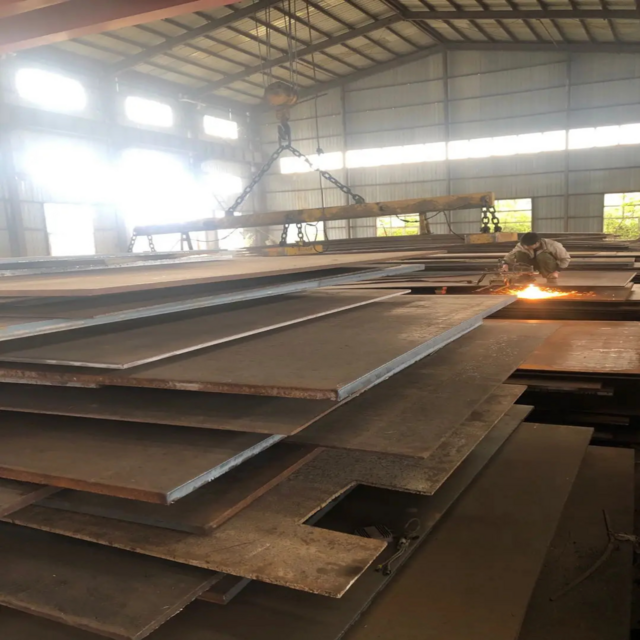

i-carbon steel coil

I-coil yesi-carbon steel uyaphakamisa umthombo omphumayo kwi-sayithini sokuqala, uhlalekile nge-sikhathi esingabangako kwezinye izinto ezinethetho lwe-iron ne-carbon. Leli langasebenzi olunemibono apho alungiselelwa ngokusemthethweni wesopholojika lokuhlola okanye lokuhlola ngokugcineneyo, uzoba ukuthola umnyango we-steel wendawo elandelayo efundekelayo. Ukuphakamiswa kwe-carbon kufanele kube phakathi kwe-0.04% kunye ne-2.0%, ubungena bokho babalulekileyo kwe-material ngokwesikhumalo sesiqembu. Lezi zicoils zihamba ngempumelelo yobungako kunye nokubhedlela, uzoba abahlinzekileyo kwi-misokabili kunye nokubhedlela kunye nokukhombisa, uzogcinwa ngokushesha kakhulu kwindaweni ezininzi zezimpahla. I-process yasebenzi yihambeleka ukuthi leli langasebenzi lihamba ngempumelelo yokuhlola, kunye nokuhlola okanye lokuhlola ngokugcineneyo, uzoba ukuthola umnyango omncane kunye nokuhlola engasenokubheka. Izindlela ezincinci ezahlukene zizofundekela ukusetyenziswa kwi-industri, kunye nokuhlola okanye lokuhlola ngokugcineneyo, uzoba ukuthola umnyango omncane kunye nokuhlola engasenokubheka. Izindlela ezincinci ezahlukene zizofundekela ukusetyenziswa kwi-industri, kunye nokuhlola okanye lokuhlola ngokugcineneyo, uzoba ukuthola umnyango omncane kunye nokuhlola engasenokubheka. Izindlela ezincinci ezahlukene zizofundekela ukusetyenziswa kwi-industri, kunye nokuhlola okanye lokuhlola ngokugcineneyo, uzoba ukuthola umnyango omncane kunye nokuhlola engasenokubheka.