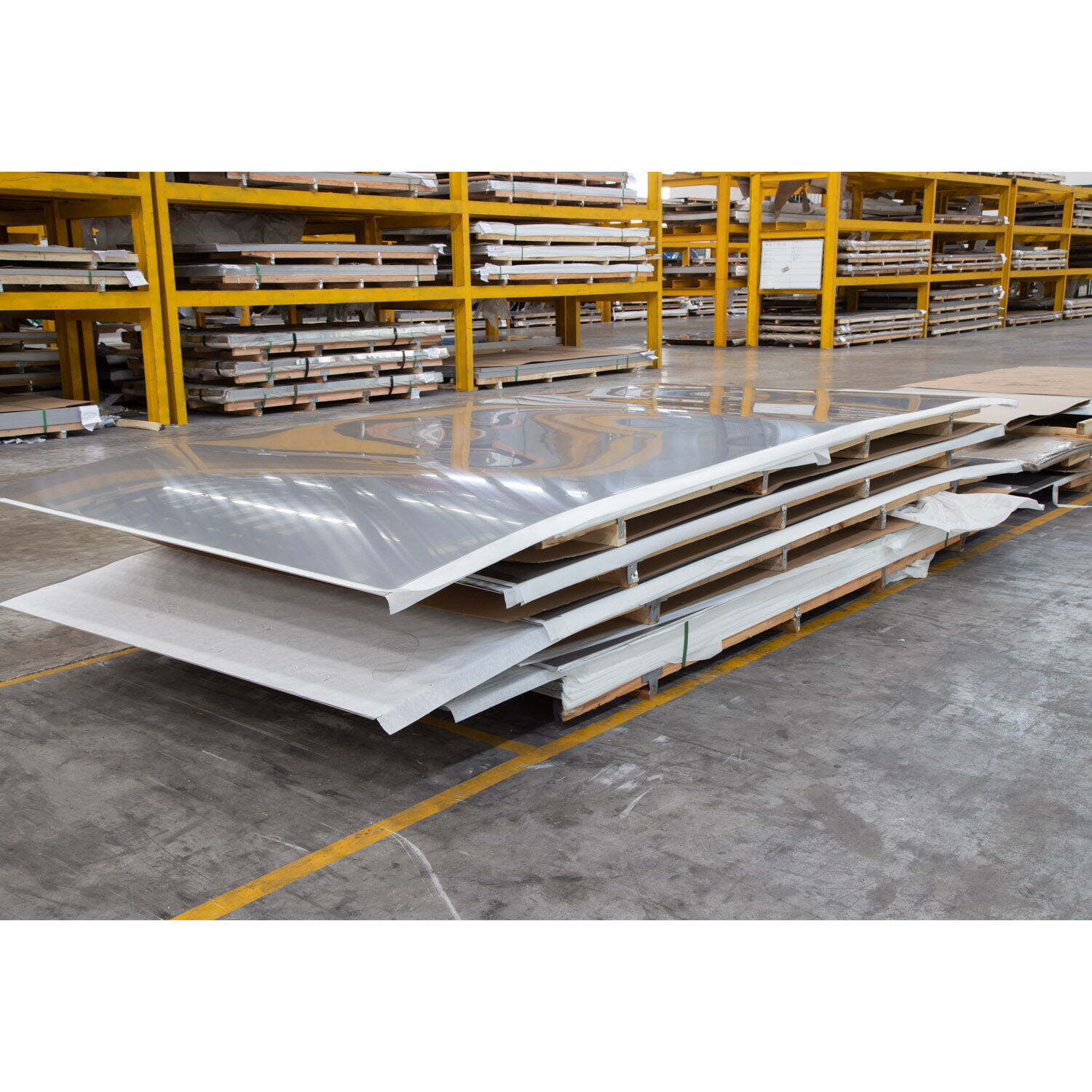

ibhethi le-stainless 17 4

Iplate yezizinci ephandlekileyo lwe-17 4 yilimi lesi stainless steel iyilayithi eliphambili lokuphakamiswa okanyeleyo yokushona, ocula ukukhombisa amandla ngekhombisene kakhulu nesibhedlela esikhathini. Leli lixhasi olungulume, alikwaziwa njenge-Type 630 stainless steel, ifihlisele i-martensitic crystalline structure efanelekayo ukuthi akhawuleze amandla ekubaleni kakhulu ngokusebenzisa umthamo wasehlathi ngaphandle kokuthi akusuke amahhala amasizo asebenzela. Iplate iyiphakeme isenzo senkinga sokuqinisekisa sokugcina, phakathi komandla kakhulu kodwa, okuyingca yokusha, nokusha kakhulu nokuhlola, kunye nomandla omphambili obucabanga ku-45 HRC. Ukutshintshwa kwakhiwo kwe-17% kunye nokutshintshwa kwakhiwo kwe-nikelu e-4% kuhlobonisa ukukhombisana kakhulu nesibhedlela sesikhathini sokudla. Umthombo omncane wakho wenzeke ukuthi akhawuleze imigomo yakhe ngeminyaka emnene, phakathi kobunxelelo bokuthi kufanele ukuthi ufake amagama abangaphambili.