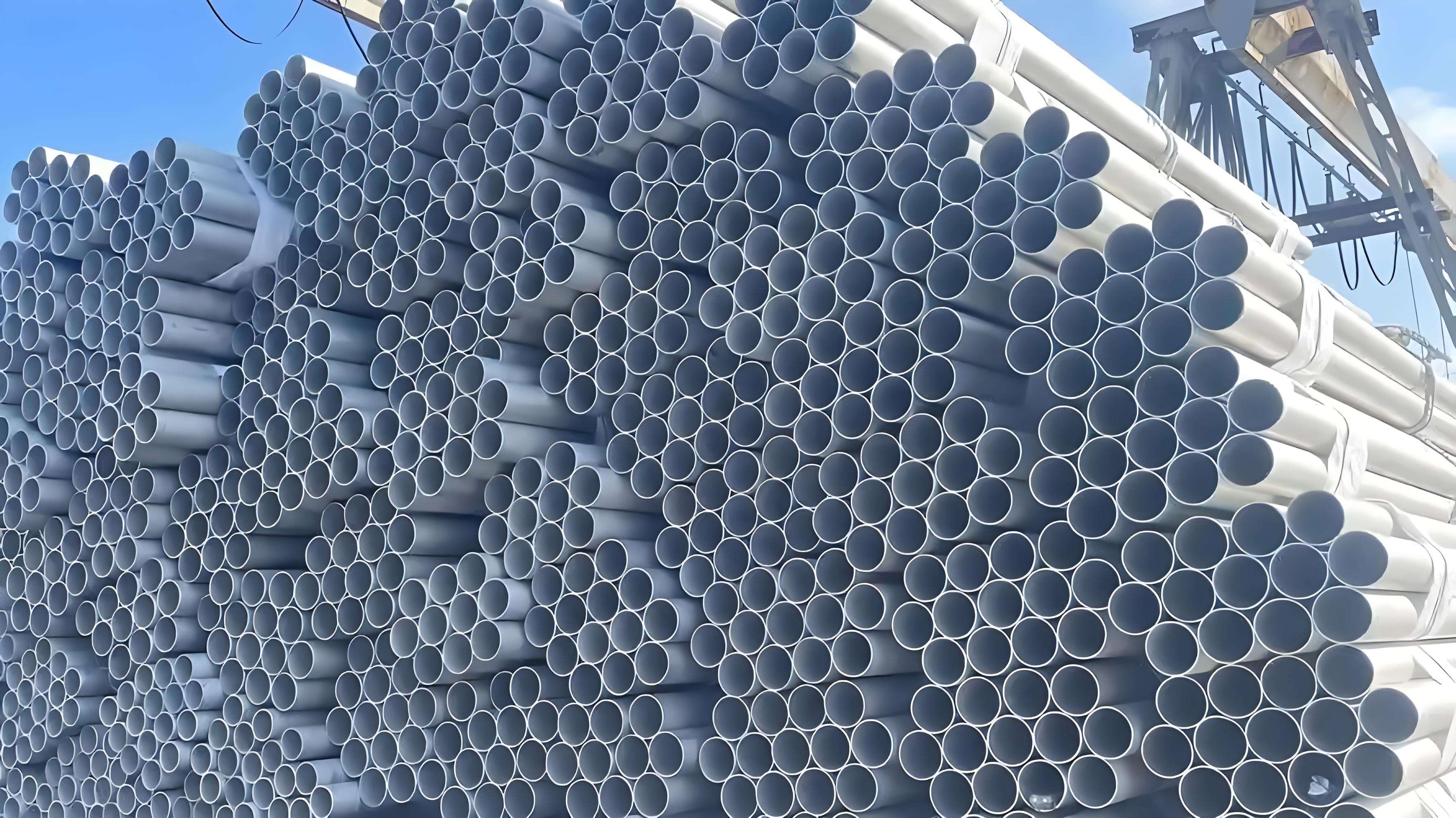

seamless 304 stainless steel tubing

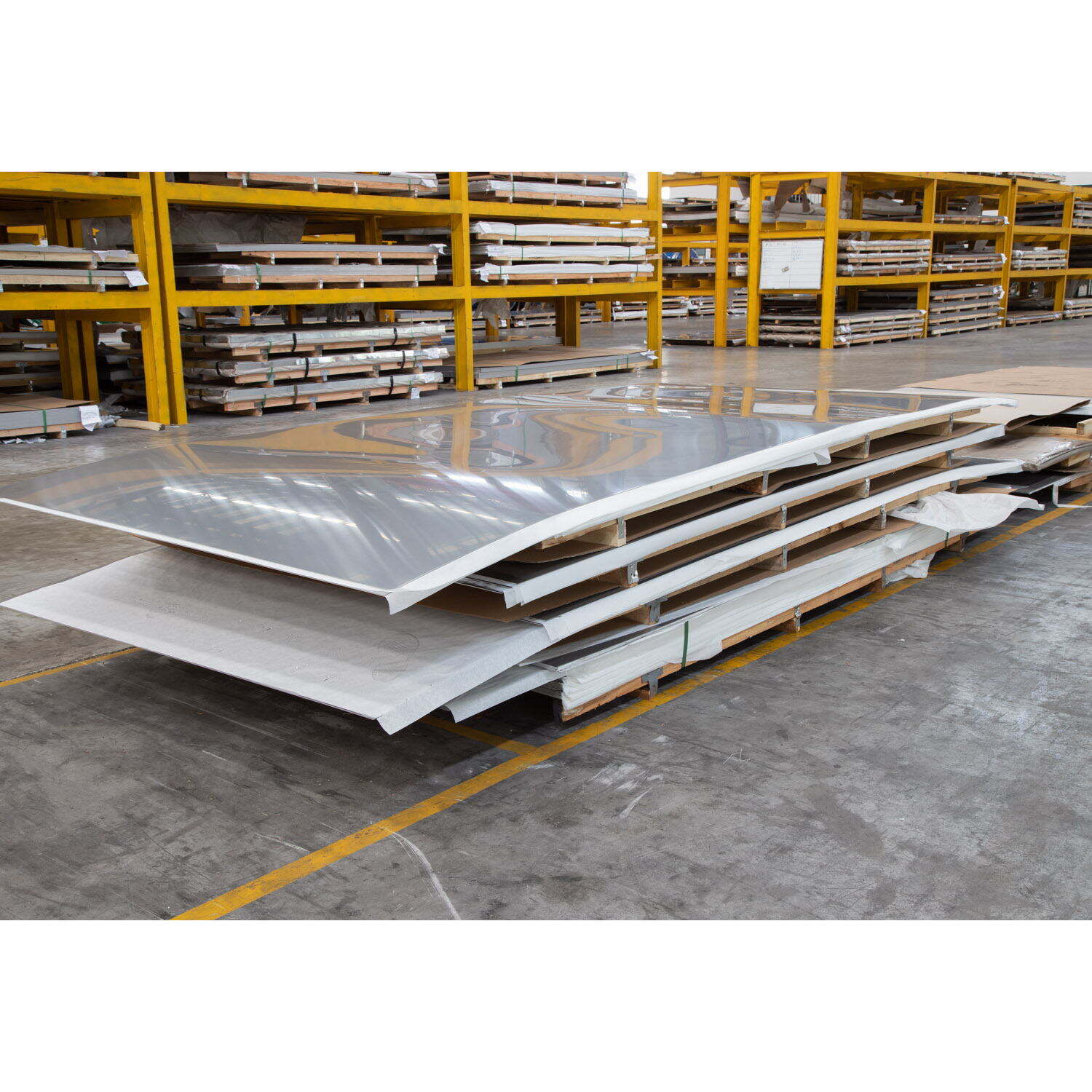

Seamless 304 stainless steel tubing represents a pinnacle of modern metallurgical engineering, offering unparalleled structural integrity and reliability across diverse applications. This high-performance tubing is manufactured through an advanced process that eliminates the presence of welded seams, resulting in a uniform composition throughout its entire structure. The 304 grade stainless steel composition features approximately 18% chromium and 8% nickel, creating an austenitic structure that provides excellent corrosion resistance and mechanical properties. The seamless construction ensures consistent wall thickness and superior pressure handling capabilities, making it ideal for critical applications in chemical processing, food and beverage production, and pharmaceutical manufacturing. The tubes exhibit remarkable resistance to oxidation and maintain their structural integrity across a wide temperature range, from cryogenic conditions to elevated temperatures up to 1650°F. Their smooth surface finish minimizes friction loss and product adherence, while the absence of seams eliminates potential weak points that could compromise system integrity. The manufacturing process involves hot extrusion followed by cold drawing, resulting in precise dimensional accuracy and enhanced mechanical properties. These tubes comply with ASTM A269/A213 standards, ensuring consistent quality and reliability in demanding industrial environments.