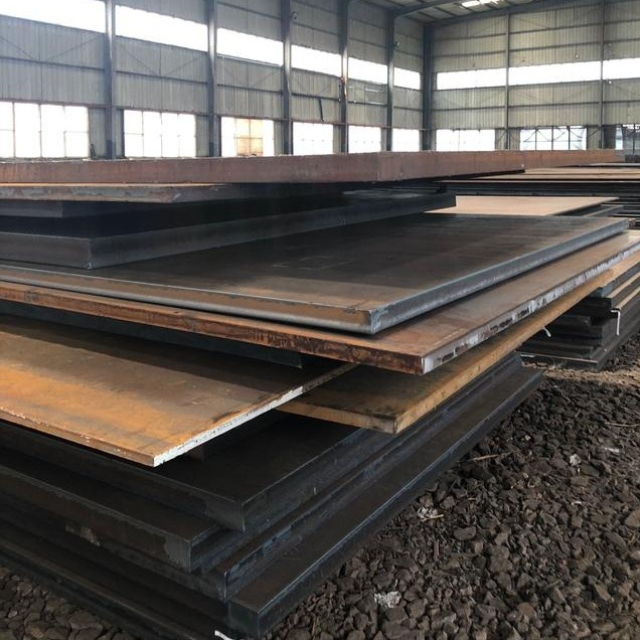

mild steel coils

Mild steel coils represent a fundamental component in modern manufacturing and construction industries, offering an optimal balance of durability, workability, and cost-effectiveness. These versatile metal products are created through a sophisticated hot-rolling process, where steel is heated and compressed into continuous strips that are then coiled for efficient storage and transportation. With a carbon content typically ranging between 0.05% and 0.25%, mild steel coils possess excellent formability and welding characteristics, making them ideal for various applications. The manufacturing process ensures consistent material properties throughout the coil, including uniform thickness, controlled surface finish, and reliable mechanical properties. These coils are available in various dimensions, thicknesses, and grades to meet diverse industrial requirements. Their applications span across multiple sectors, including automotive manufacturing, construction, home appliances, and industrial equipment. The surface quality of mild steel coils can be customized through different finishing processes, such as pickled and oiled, cold-rolled, or galvanized, enhancing their resistance to corrosion and improving their aesthetic appeal. Modern production techniques incorporate advanced quality control measures, ensuring that each coil meets stringent industry standards for dimensional accuracy, surface quality, and mechanical properties.