carbon steel coil suppliers

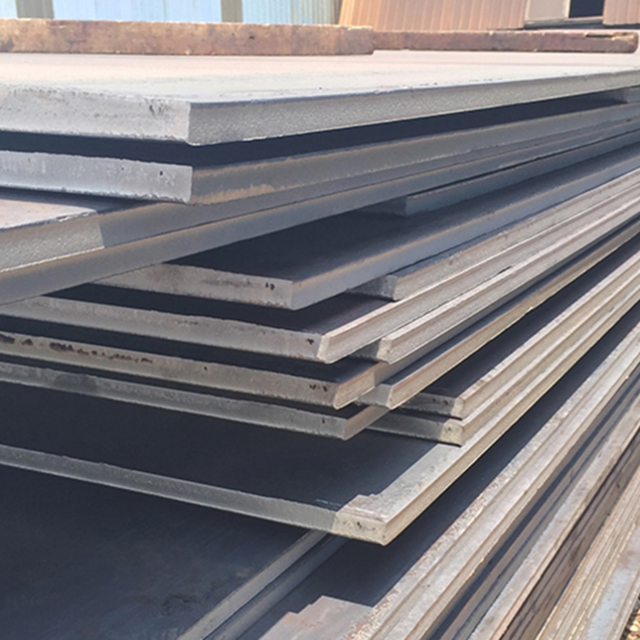

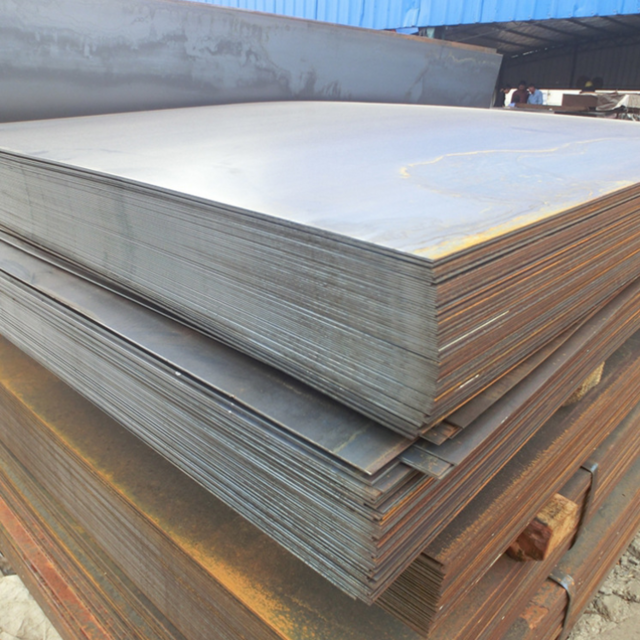

Carbon steel coil suppliers play a crucial role in the global metal industry by providing essential materials for various manufacturing sectors. These suppliers specialize in producing and distributing high-quality carbon steel coils that meet diverse industrial requirements. Carbon steel coils are manufactured through advanced rolling processes, ensuring consistent material properties and dimensional accuracy. These coils are available in various grades, thicknesses, and widths to accommodate different applications. Modern suppliers utilize state-of-the-art production facilities equipped with precision control systems to maintain product quality. They typically offer hot-rolled, cold-rolled, and galvanized options, each serving specific industrial needs. Quality control measures, including chemical composition analysis and mechanical testing, are implemented throughout the production process. Suppliers often maintain extensive inventory systems and efficient logistics networks to ensure timely delivery to customers worldwide. The industry emphasizes sustainability practices, incorporating recycling programs and energy-efficient production methods. Many suppliers also provide value-added services such as slitting, cutting to length, and surface treatment options. They serve diverse sectors including automotive, construction, appliance manufacturing, and infrastructure development. Technical support and consultation services are typically available to help customers select the most suitable materials for their applications.