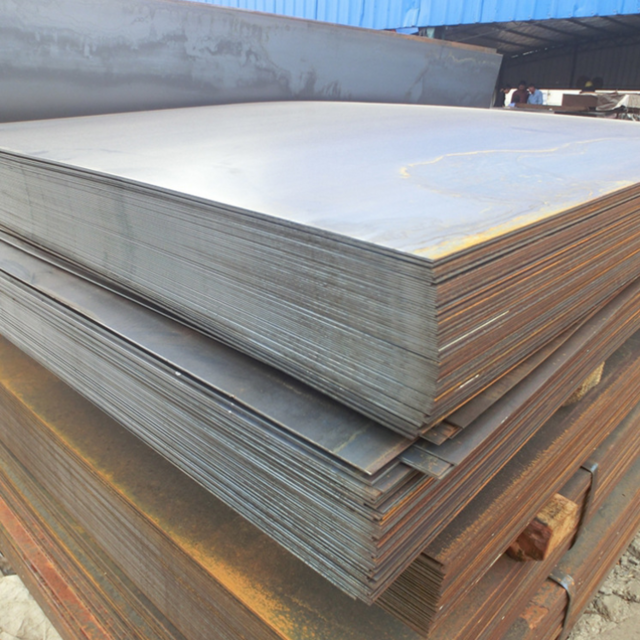

1023 carbon steel sheet

The 1023 carbon steel sheet stands as a versatile and widely used low carbon steel material, containing approximately 0.23% carbon content. This composition provides an optimal balance between strength and formability, making it ideal for various industrial applications. The material exhibits excellent weldability and machinability characteristics, allowing for easy fabrication and processing. Its mechanical properties include a yield strength typically ranging from 205 to 275 MPa and tensile strength between 380 and 460 MPa. The 1023 carbon steel sheet demonstrates remarkable durability in standard environmental conditions and responds well to various surface treatments and coatings. Its uniform microstructure ensures consistent performance across applications, while its cost effectiveness makes it a practical choice for large scale manufacturing. The material's ability to withstand moderate stress and its good ductility make it particularly suitable for structural components, automotive parts, and general fabrication work. Additionally, its thermal conductivity properties and resistance to wear under normal conditions contribute to its widespread use in industrial equipment and machinery components.