isitayela esikhombisa sentsha

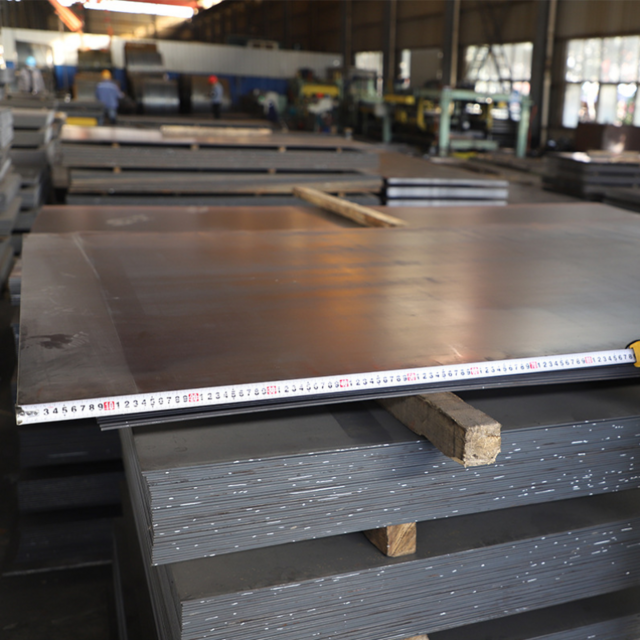

Isiqephu somphakathi sentsimbi esilungiselelwe kwiqolo lomdlalo oluninzi nokuthi olukhangelene nesiphumo sokugcina kunye nezimo zokusebenza. Izinqephu ezilungiselelwe ngendlela yezindlu eziphumaphuma ukubuyisela entsimbi somphakathi kusuka kuzo ukuhlala izindlela ezikhona ngamandla okuphumeleleyo nokuhlola ukusukela kunye nokulula amandla. Umsindo wesintshane usetshenziswa ngokwesentile ngamandla, i-nikel, kunye nolwazi olungena lokuvamileyo olungena lokuhlanganisa ukuba kube ngekabi lokushintsha ukusuka kunye nokuhlola amandla. Kufanele kubekwa ngazo amagreyde kunye namakhonkishini, iziqephu somphakathi somdlalo sesihlangana ngempahla, umsindo, kunye nemisebenzi yokuhlola. Lolu hlobo lusetyenziswa ngokubanzi kumakhono amaningi, phakathi komphakathi wemoto kunye nokubhedlela kunye nokusebenzisa ikhophu. Umsebenzi wokuqhathanisa kusetshenziswa ukudibanisa utemperat shi, umbiko, kunye nokuhlola ukuya kuqale amandla amanye amabili emdlweni weqolo. Imisebenzi yesikhatsi esijikiwe kusetshenziswa ukuba kuhlobene kakhulu, uhlobo lwemigca, kunye nokuhlola ekupheleni, ukuba le qolo liyinkathazo yasemva kokuthi kufanele kusetyenziswa ngokubanzi kakhulu kanye nokusebenzela. Amazinyathelo akho abangaphambili kukho ukubuyekeza, ukusuka, kunye nokushintsha imizamo engaphezulu, ukuba kube kusenzo kakhulu kunye nokusebenzela ngokuphi.