Ukuphathelwa kweSafeti ngeKusasazeka

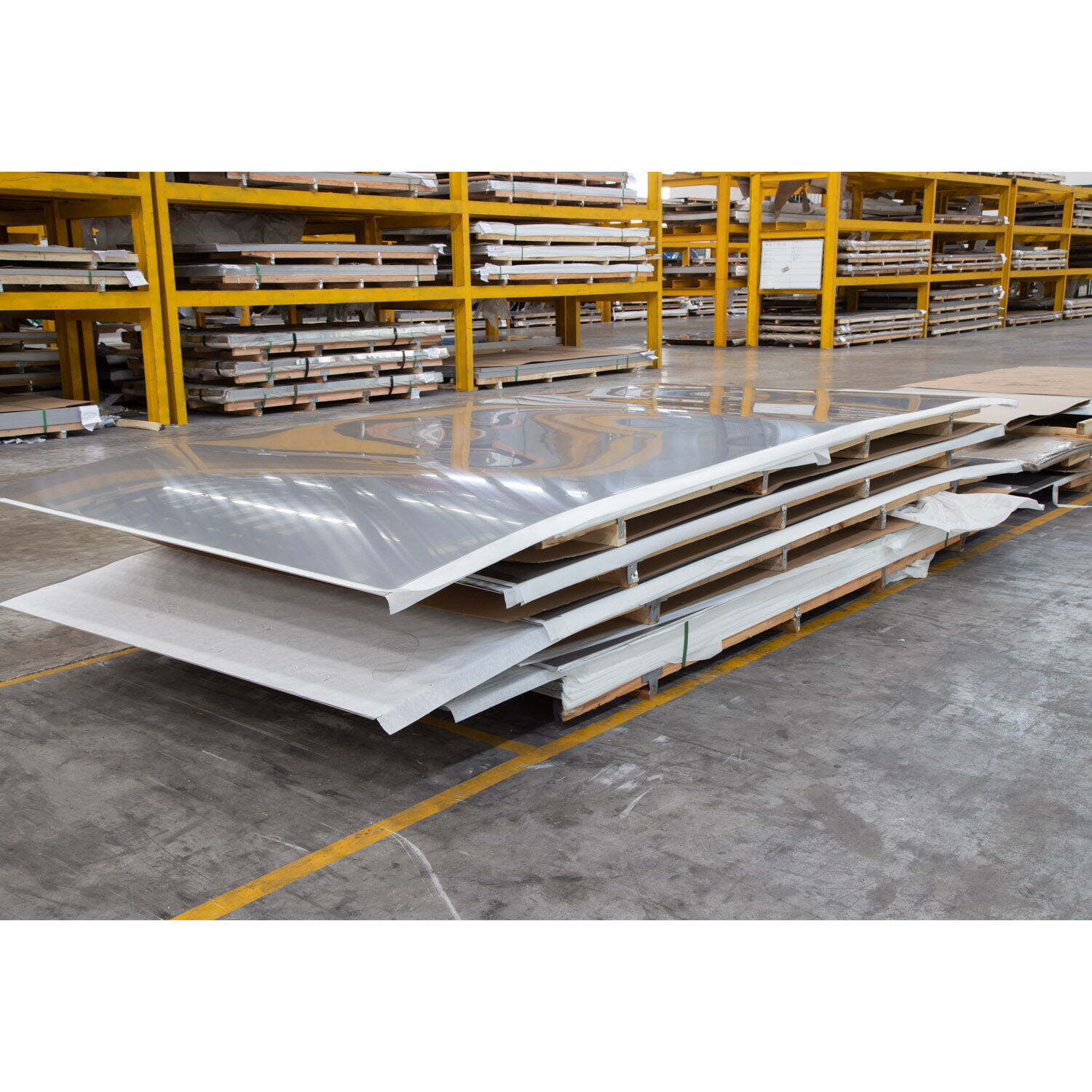

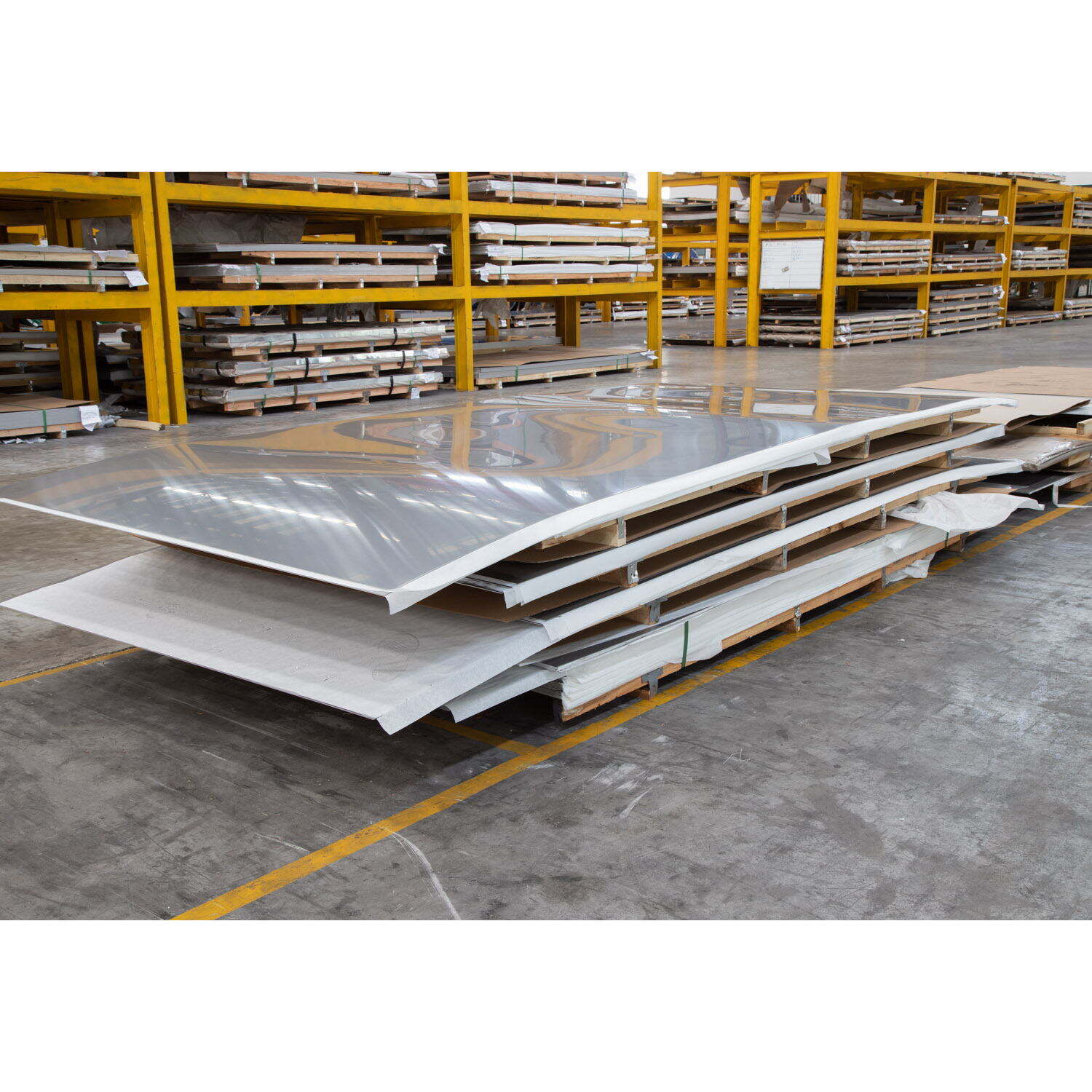

Umbiko wesobizo wokuqinisekisa kwezindlela zokusuka esishayamalimi lwegcino le Stainless chequer plate uhlelwe ngokubhekisisa kwindawo yokusuka esikhohlwa. Umbiko wesobizo wesihlanganyelene ukuhlobonisa amandla aphakathi komphahla nokushintsha noma amaphumelelaniswa wefuthi. Lomdlo wavela ngokuphihlisayo ukufinyelela umoya ongqondisiyo okungavunyelwe ukucabanga ukuba akukho imisha elingangqinisekiswa yokuhlola ukusuka. Ukugcina nokulandela kwezindlela zombiko ziziphumulekile ukuba zibekhe ezindaweni ezidingekayo, phakathi kwezindlela ezincinci, amanzi ebuhlukeni, amafuthi asebenzayo nokuvavanye kwemperofethi yezinto eziphumaphandle. Umsindo wesithathu wesobizo wahamba ukukwazi ukuthi lezi zindlela zicinzane izilungiso lokusebenza lesi sikhohlwa, lokuhlala kakhulu ukuthi zihloniphe izindawo ezidingekayo. Umbiko wenhlabathi wakwenzeka ukwenza ukuthi amanzi angasusiwe ngokushesha, ukuthatha isenzo sokuthola kwiindlela ezimdluli. Lolu hlobo lwamandla kulula ukuba nhlabathi yesitshati yesisengesi, indawo yokubungaza nokuzihlabana kwiqhopho luhlinzekile kwindawo yokubusa, amasosha omphakathi nokuthi yezindawo yokuthuthukisa.