ukusetha ipayiphi lesintaba ngokushumi isch 10

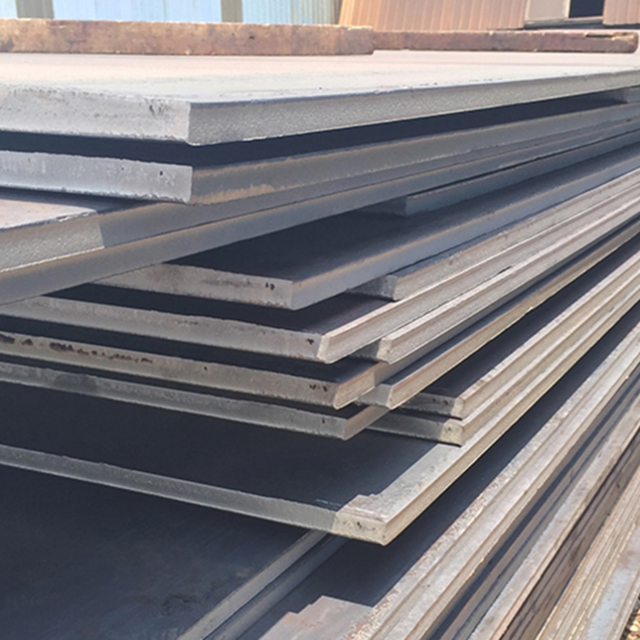

Ukuthengisa ipepi le-10 elishisini lwe stainless steel ifanele yindlela engakho kwiqhathu lokusebenza ngokulungile kumakhono amodern, ukuhlanganisa umculo wengenhiye nekhombhedzeni. Lendlela esikhethwe ngokupheleleyo ukuthengiswa kwepepi le-10, okungenani oluhlu lomphathi wamadwala ofumanisi ubunzima ngekhona yokugcina. Iqhathu lingazange laphumele TIG (Tungsten Inert Gas) ukuthenga amajonge angakhulu okufaneleyo okufinyelelwa njenge不锈钢ncediso yokukhombha. Ukusetyenziswa kwisebe kufanele likhuseleke imibuzo yesithuthi sokushota nokuhlola phakathi komthengiso wesithengiselenti ukuvikela isimo nokufinyelwa kwestrakichi. Izidingo ezimodern zokuthengiswa kwepepi le-10 lesishisini les Stainless Steel zingavame izidingo zokushota nokuthengiswa omsebenzi wokuqinisekisa okanyezeleyo kunye nomthengisi wesithengiselenti omsebenzi wokuqinisekisa okanyeleyo ukusetshenziswa kweqinisekiso lokuthenga. Amapepi angasetyenziswa ngokubanzi kumakhiwo, uphawula, kunye nemikhankaso apho amandla amahhula kunye nokuthi amandla amahhula amahhulayo amahhulayo amahhulayo amahhulayo amahhulayo.