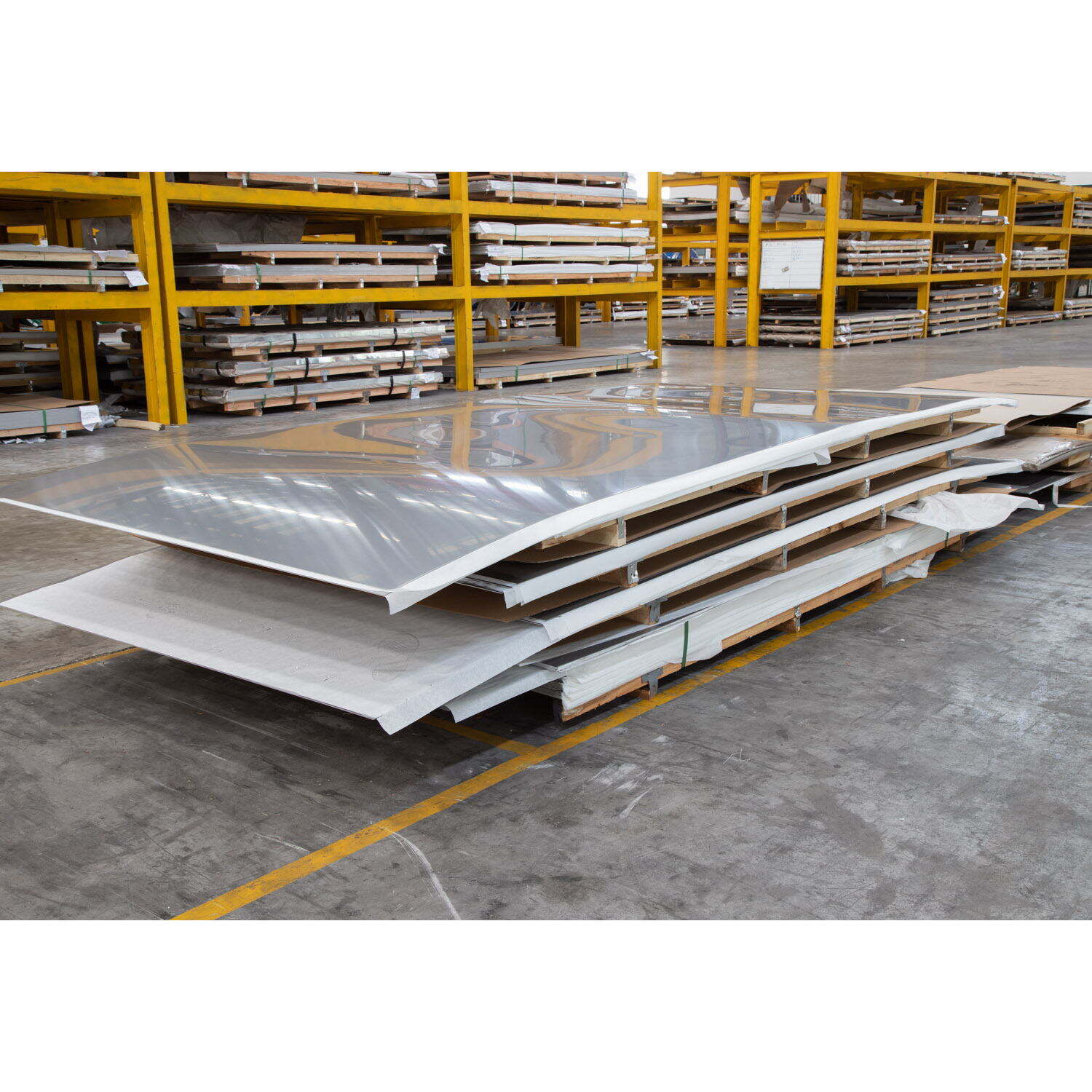

stainless steel coil stock

Stainless steel coil stock represents a versatile and essential material in modern manufacturing and construction industries. These precisely engineered metal coils are produced through an advanced rolling process that ensures consistent thickness, superior surface finish, and optimal mechanical properties. The material consists of various grades of stainless steel, typically including austenitic, ferritic, and martensitic varieties, each offering specific performance characteristics. The manufacturing process involves careful control of temperature, pressure, and cooling rates to achieve desired metallurgical properties. These coils are available in different widths, thicknesses, and finish options, making them suitable for diverse applications. The material's inherent corrosion resistance, combined with its exceptional strength-to-weight ratio, makes it ideal for both indoor and outdoor applications. Industries ranging from automotive and aerospace to food processing and architectural construction rely heavily on stainless steel coil stock for their manufacturing needs. The material's ability to maintain its structural integrity under varying environmental conditions, coupled with its aesthetic appeal, has made it a preferred choice for both functional and decorative applications.