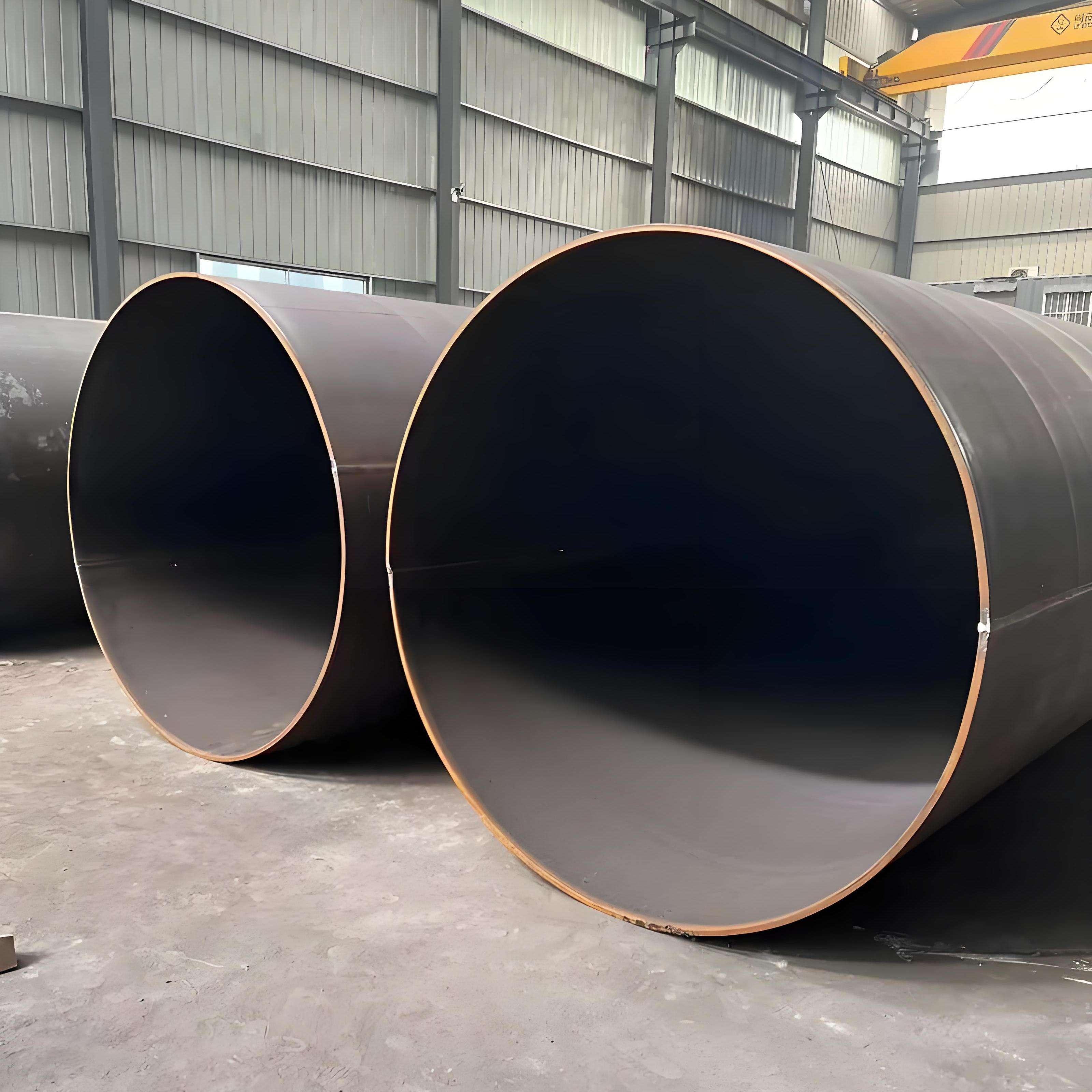

sch 80 carbon steel pipe

Schedule 80 carbon steel pipe represents a heavy-duty industrial piping solution characterized by its thick walls and exceptional durability. This high-strength piping system is manufactured according to strict ASTM standards, featuring a wall thickness significantly greater than standard pipe options. The enhanced thickness of Schedule 80 provides superior pressure resistance and structural integrity, making it ideal for demanding industrial applications. These pipes are crafted from high-quality carbon steel, which undergoes precise manufacturing processes to ensure consistent quality and reliable performance. The material composition typically includes a carefully balanced mixture of carbon and iron, with trace elements added to enhance specific properties. Schedule 80 carbon steel pipes are designed to handle extreme pressures and temperatures, making them suitable for both high-pressure and high-temperature applications. They excel in conveying various fluids, including water, steam, chemicals, and petroleum products. The pipes feature standardized dimensions and threading specifications, ensuring compatibility with a wide range of fittings and accessories. Their robust construction provides excellent resistance to mechanical stress, impact, and vibration, while also offering good corrosion resistance when properly treated or coated.