rolled and welded steel pipe

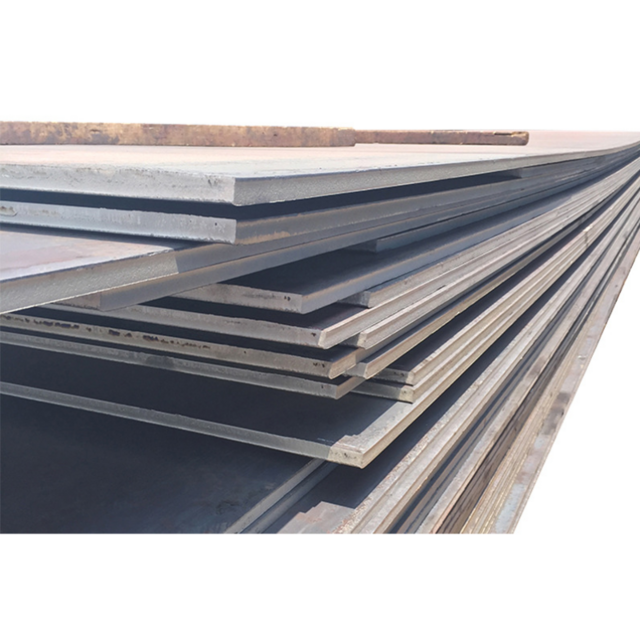

Rolled and welded steel pipe represents a cornerstone of modern industrial infrastructure, combining robust manufacturing processes with versatile applications. This type of pipe is manufactured through a sophisticated process where steel plates or strips are first rolled into cylindrical shapes and then welded along the seam to create a continuous, sturdy pipe. The manufacturing process begins with high-quality steel sheets that undergo precise rolling operations to achieve the desired diameter and wall thickness. The welding process, typically performed using advanced techniques such as electric resistance welding or submerged arc welding, ensures structural integrity and reliability. These pipes are engineered to meet stringent industry standards, offering exceptional strength-to-weight ratios and remarkable durability in various operating conditions. The versatility of rolled and welded steel pipes makes them indispensable in numerous applications, from oil and gas transportation to construction and industrial processing. They can be manufactured in a wide range of sizes, with diameters ranging from small-bore pipes to large-diameter conduits, and wall thicknesses tailored to specific pressure requirements. The pipes feature uniform wall thickness, excellent roundness, and superior surface finish, making them ideal for both above-ground and underground installations.