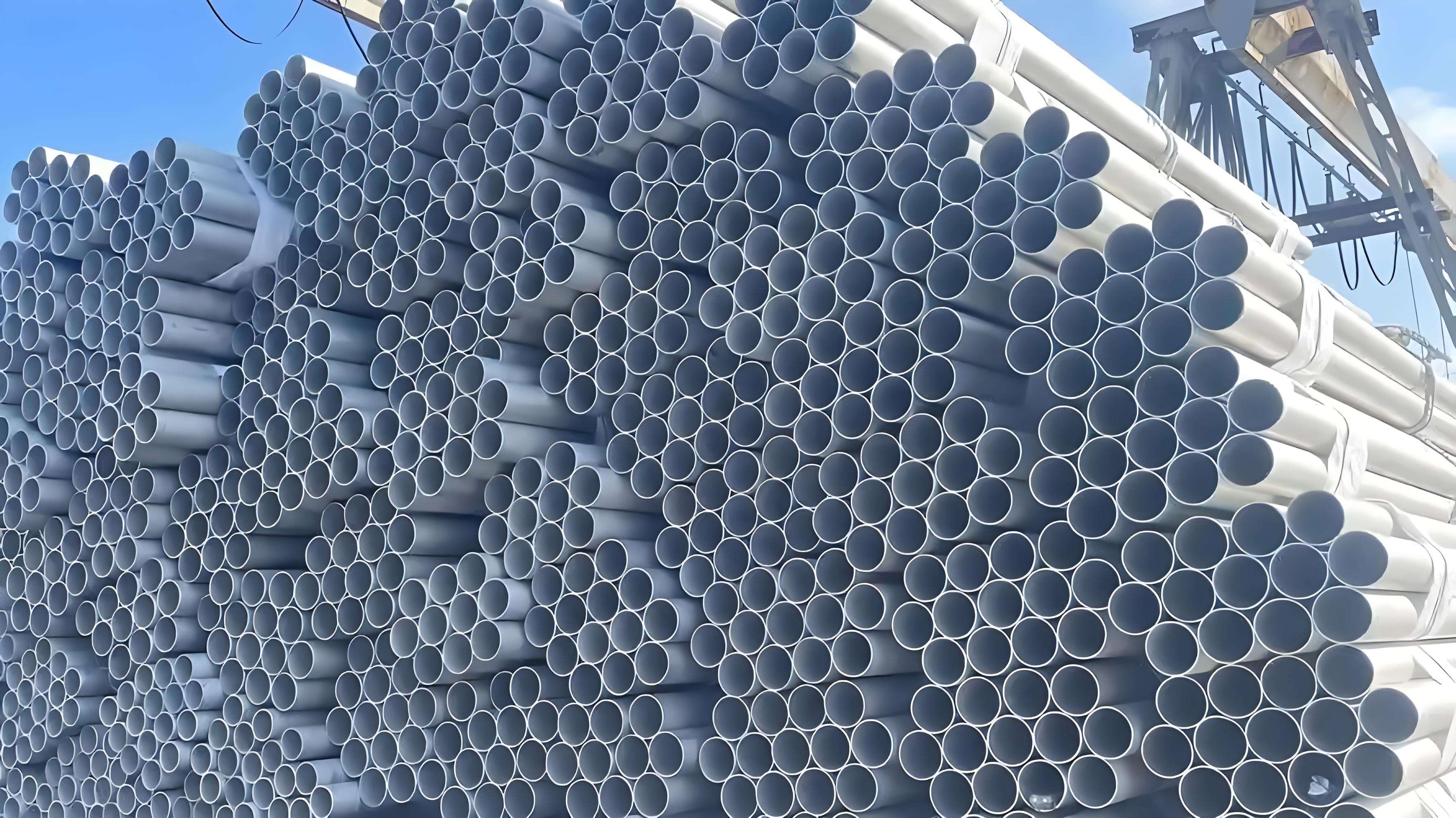

316l stainless steel pipe

316l stainless steel pipe represents a premium grade austenitic stainless steel product that offers exceptional corrosion resistance and durability. This specialized pipe is manufactured with low carbon content, typically less than 0.03%, which significantly reduces the risk of carbide precipitation during welding processes. The pipe's composition includes chromium, nickel, and molybdenum, creating a robust material that excels in demanding environments. In industrial applications, 316l stainless steel pipe proves invaluable for transporting corrosive materials, chemicals, and pharmaceuticals. Its superior resistance to pitting and crevice corrosion makes it particularly suitable for marine environments and coastal installations. The pipe's mechanical properties ensure reliable performance across a wide temperature range, from cryogenic conditions to elevated temperatures up to 800°C. Furthermore, its excellent fabricability allows for various joining methods, including welding, threading, and mechanical coupling. The smooth surface finish of 316l stainless steel pipe also contributes to optimal flow characteristics and minimizes the risk of contamination, making it ideal for sanitary applications in food processing and medical facilities.