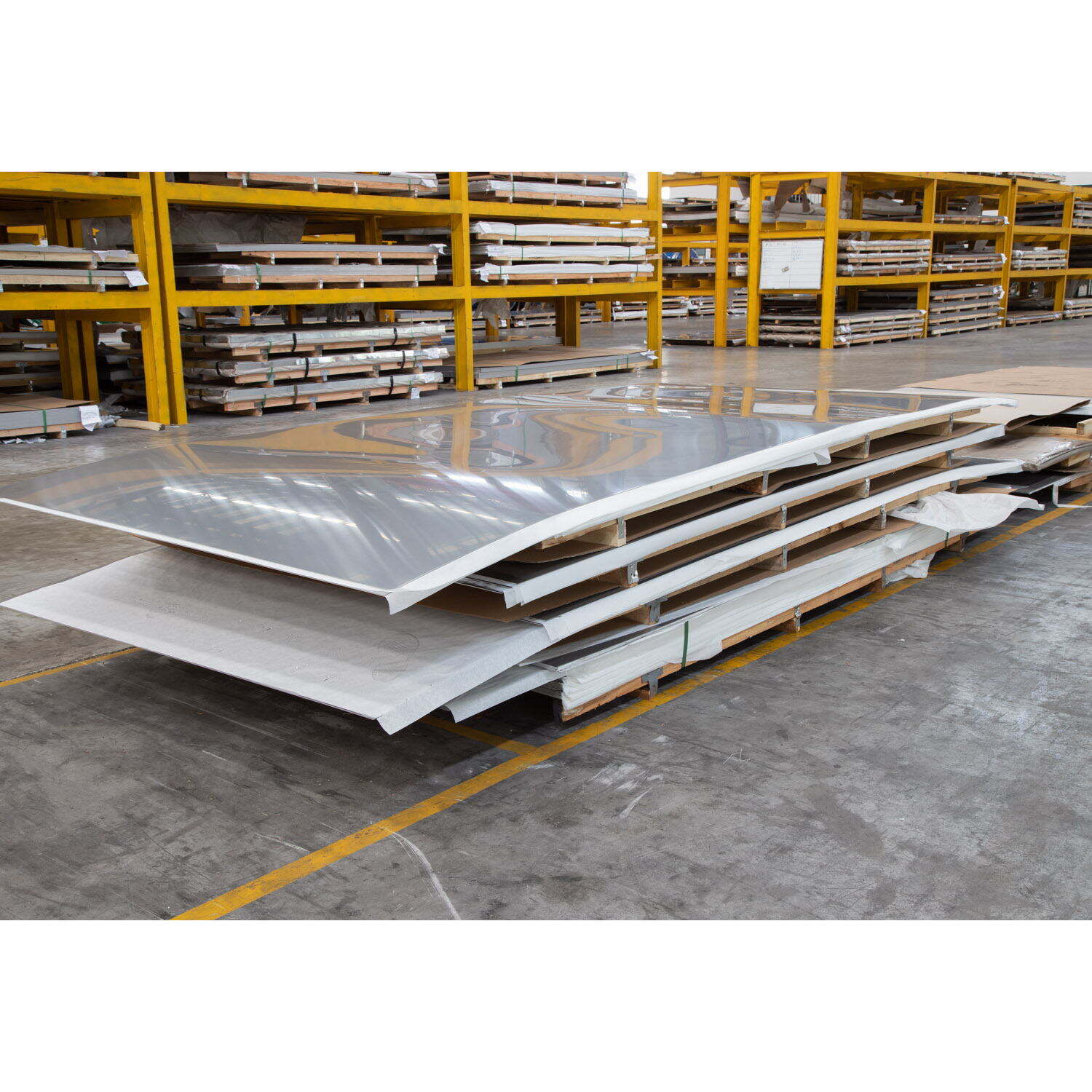

310s stainless steel plate

The 310S stainless steel plate represents a high-performance austenitic stainless steel grade engineered for extreme conditions. This remarkable material features exceptional heat resistance capabilities, maintaining structural integrity at temperatures up to 1150°C. The plate's composition includes approximately 25% chromium and 20% nickel, creating a robust material that excels in corrosion resistance, particularly in aggressive environments containing sulfur and other oxidizing elements. The 310S variant specifically contains lower carbon content, which enhances its weldability and reduces the risk of carbide precipitation during high-temperature operations. These plates find extensive applications across various industries, including petrochemical processing, furnace components, heat exchangers, and chemical processing equipment. The material's unique combination of strength, durability, and resistance to oxidation makes it particularly valuable in manufacturing equipment that operates in high-temperature environments. Additionally, its excellent formability allows for versatile fabrication options, while its non-magnetic properties make it suitable for specialized applications where magnetic interference must be avoided.