Manufacturing Processes of Stainless Steel Pipes

How Seamless Pipes Are Produced (Extrusion Method)

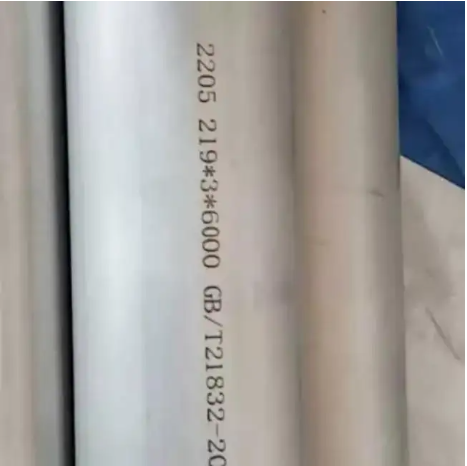

Extrusion lies right at the heart of making those seamless stainless steel pipes we see everywhere from construction sites to industrial plants. The basic method starts with heating up cast steel billets until they reach around 2,300°F (about 1,260°C), which makes them pliable enough to work with. Once hot enough, these billets get pushed through specially designed dies that shape them into long hollow tubes as they cool down. Getting the temperature just right matters a lot here because if the metal gets too cold, it won't stretch properly, but let it get too hot and everything becomes a mess. Most factories spend considerable time fine tuning their heat settings based on what kind of final product they need. After extrusion comes another round of adjustments where operators roll and stretch the material further inside climate-controlled chambers to hit exact specifications for diameter and wall thickness according to ASTM standards.

Keeping quality under control during extrusion is really important if we want reliable products at the end. The whole process has sensors and automation watching over things like how thick the walls are getting and whether the surface looks smooth enough. When workers do their detailed checks, they're looking out for problems that might show up - maybe some bumps on the outside or areas where the metal isn't quite thick enough. All these strict checks make sure that when those seamless pipes go into service, they can handle whatever application needs them, especially ones where there's lots of pressure involved and the structure just has to hold together no matter what.

Welded Pipe Fabrication Techniques (ERW & Longitudinal Welding)

Stainless steel pipes that are welded get made using what's called Electric Resistance Welding, or ERW for short, along with something called longitudinal welding. What makes ERW stand out is how efficient it actually is. Basically, electricity creates heat that melts together the edges of a steel strip, then forms them into a pipe shape. Traditional welding methods need all sorts of extra filler stuff, but ERW skips that part completely. This means lower costs overall and fewer chances for things to go wrong during production. Without needing those extra materials, the finished pipe ends up looking much smoother on the surface. That smoothness matters a lot when these pipes are used in food processing plants or chemical facilities where even tiny imperfections could cause problems down the line.

In longitudinal welding, manufacturers roll out a flat steel sheet into a cylinder shape before making the weld run along the length of the pipe. This method works well when bigger diameter pipes are needed but comes with tradeoffs against seamless alternatives. On the plus side, production costs drop significantly and factories can crank out products faster. The downside? That weld line remains vulnerable spot where structural integrity might weaken over time, especially when exposed to harsh environments that cause corrosion issues down the road.

Welded pipes tend to win out in mass production scenarios because they require simpler manufacturing processes and consume fewer resources overall. That said, when projects demand maximum strength and reliability, many engineers still go with seamless pipes even though they come at a premium price. Real world decisions usually hinge on what matters most for each particular application. Some construction sites might prioritize budget constraints while others need materials that can withstand extreme conditions without failing. The tradeoff between initial costs versus long term performance remains a key consideration throughout the selection process.

Strength and Structural Integrity Comparison

Pressure Distribution in Seamless vs. Welded Designs

Knowing how seamless versus welded pipes behave mechanically matters a lot when evaluating how they'll perform under pressure situations. Seamless pipes generally spread pressure more evenly throughout their entire structure because there's no weld seam running through them. The material is consistent all around, which means these pipes can take on greater stress before failing. That's why engineers often specify seamless pipes for really important jobs such as transporting crude oil through pipelines or setting up equipment where pressure spikes might occur. Welded pipes work differently since they're made by fusing together separate pieces of steel. These joints create areas that sometimes fail first when pressure builds up, though modern welding methods have definitely made these connections much stronger than they used to be in the past.

Seamless pipes find their place mainly in situations needing to hold up under serious pressure with little room for failure, think power plants or chemical factories where things can get pretty intense. On the flip side, welded pipes still see lots of action when money matters most and getting something built fast takes precedence over extreme pressure handling. Many plumbers actually prefer these welded versions for regular household installations because they work just fine for everyday water pressure without breaking the bank. The construction industry has long relied on this cost effective option for non critical systems throughout residential buildings.

Weak Points in Welded Joints (Heat-Affected Zones)

Heat affected zones (HAZ) form during welding and represent one of those key points engineers need to check when looking at how strong a welded joint really is. These zones develop because welding generates intense heat that changes the metal structure right around the weld area. What happens next? Well, this change often means weaker spots that break easier under stress. Studies show welded connections actually fail more frequently than seamless ones, particularly when dealing with extreme temperature swings or pressure changes in pipelines. The Journal of Welding Research backs this up, so it's something manufacturers definitely want to watch closely in their quality control processes.

There are ways to deal with these problems though. Post weld heat treatments work well, along with newer methods like laser welding or friction stir welding that actually reduce how much of the material gets affected by heat during the process. This helps create stronger joints overall. Choosing the right filler material matters too, and making sure to check everything thoroughly after welding is pretty important for keeping those pipe structures strong over time. Even when dealing with tricky heat affected areas, properly treated welded pipes still perform reliably across many different industries from oil pipelines to construction sites where structural integrity counts.

Corrosion Resistance and Longevity Factors

Galvanization Challenges in Welded Pipes

Galvanizing welded pipes does boost their ability to resist corrosion, but there are limits to how effective it really is. While the zinc coating acts as protection from outside elements, these pipes still face much faster corrosion when placed in harsh places such as coastal areas or factories handling chemicals. We've seen cases where even with proper galvanization, the weld points start deteriorating pretty quickly after installation. Material selection matters a lot here too. Going for better quality base metals and applying more thorough surface prep before galvanizing makes a real difference. Some companies have had good results using special alloy combinations along with extra cleaning steps that prepare the metal surface properly for the zinc coating to stick better.

Seamless Pipe Performance in Harsh Environments

In tough industrial settings, seamless pipes tend to last much longer than welded ones. Without those pesky seams where problems can start, they don't have weak spots that get eaten away by corrosive stuff. Take oil refineries for example researchers there found that when exposed to acid, seamless pipes held up way better over time compared to their welded versions. Industry pros who've worked on pipeline maintenance back this up all the time. They point out how the solid construction of these pipes really matters in places where chemicals are constantly attacking metal surfaces. Adding alloys like chromium and molybdenum gives them extra protection against rust and decay, so companies keep seeing these pipes working reliably even after years of exposure to harsh conditions.

Cost Analysis and Budget Considerations

Production Cost Differences (Complexity vs. Efficiency)

When looking at how much it costs to make seamless versus welded pipes, there are several things to take into account. Material prices, what workers get paid, and machine running costs all play a role here. Seamless pipes generally come with bigger price tags right from the start because making them requires this complicated extrusion and drawing process that needs special machines nobody else owns. Welded pipes on the other hand usually cost less when produced since manufacturers work with flat rolled steel sheets or plates that get fused together via welding techniques. But wait a minute folks - don't forget about what happens down the road! Even though seamless pipes hit wallets harder initially, they often need less fixing up later on and last way longer than their welded counterparts. So plant managers need to do some real thinking before picking one option over another. The big question is whether spending extra money now will actually save cash later depending on where these pipes end up being used in actual operations.

Long-Term Maintenance Expenses

Looking at maintenance costs over time, seamless pipes tend to cost less because they're built stronger from the start. These pipes don't leak as easily or develop weak spots, which is why many facilities choose them for places where pressure and heat run high. Welded pipes tell a different story though. They often need checking and fixing more regularly since problems can pop up at the weld seams. Some real world numbers back this up too – most plants find themselves spending more on repairs for welded pipes than seamless ones throughout their useful life. Smart operators set up routine checks and maintenance plans right from installation day. For stainless steel specifically, getting the surface treatment right matters a lot. Installers who follow good practices instead of cutting corners will see these pipes last much longer, saving money year after year.

Applications and Industry-Specific Recommendations

Oil/Gas and High-Pressure Scenarios (Seamless Advantage)

In the oil and gas sector, seamless pipes play a critical role particularly when dealing with high pressure situations that demand solid construction. Compared to welded alternatives, these seamless versions stand up better against pressure fluctuations and generally last longer. They work great for transporting crude oil, supporting drilling equipment, and containing materials at extreme pressures. Field reports indicate welded pipes tend to fail more frequently when pushed to their limits, which explains why most experienced engineers prefer seamless options whenever reliability matters most. Choosing seamless isn't just about avoiding problems either it meets strict safety regulations too, something regulators look for closely in pipeline projects. Anyone involved in infrastructure planning would do well to specify seamless pipes for any application where long term performance under stress is absolutely necessary.

Construction and Plumbing Use Cases (Welded Pipe Suitability)

The construction and plumbing industries tend to favor welded pipes because they save money and are faster to produce. These pipes work great when time is tight on job sites needing frequent changes or adjustments since workers can bend them around obstacles and modify connections without much hassle. Flexibility matters a lot at construction sites where deadlines loom large and unexpected challenges pop up daily. Most contractors find that welded pipes still hit all the necessary industry specs even though they come in at a lower price point compared to other options. With cities expanding everywhere, we're seeing more builders turn to welded pipes simply because they get the job done quicker without breaking the bank while still meeting those important safety regulations everyone cares about these days.

FAQs

What is the main advantage of seamless pipes over welded pipes?

Seamless pipes have no welded seams, providing uniform strength and the ability to handle higher pressure levels, making them ideal for critical applications.

Are welded pipes always cheaper than seamless pipes?

Welded pipes generally have lower initial production costs due to simpler manufacturing processes. However, long-term maintenance expenses may be higher compared to seamless pipes.

Why are seamless pipes preferred in the oil and gas industry?

Seamless pipes are preferred due to their superior pressure handling capacity, necessary for high-pressure oil and gas applications.

How can corrosion in welded pipes be minimized?

Using corrosion-resistant alloys, galvanization, and advanced surface treatments can help minimize corrosion in welded pipes.

Is galvanization equally effective for both welded and seamless pipes?

Galvanization is more effective on seamless pipes as welded joints may degrade faster in aggressive environments despite the protective layer.