Understanding Your Project Requirements

Assessing Environmental Conditions

Picking out the correct stainless steel seamless pipe starts with looking at what kind of environment the installation will face. Temperature swings, different humidity levels around the area, plus any chemicals present all matter when choosing materials for pipes. Take coastal installations for example where saltwater can really eat away at standard grades. These locations need special corrosion resistant options just to last through regular wear and tear. Regulations from places like the EPA or local government bodies should factor into decisions too since these rules often dictate what types of piping are allowed in certain areas. Looking ahead makes sense as well because climate patterns change over years and decades. A pipe installed today might not hold up properly against conditions that develop down the road. Planning for these possibilities keeps systems working properly while staying within legal requirements for much longer than expected.

Determining Pressure and Temperature Needs

Knowing what pressure and temperature levels the system will face is key when picking out stainless steel seamless pipes. The chosen pipe needs to handle all those stresses without breaking down over time. Most industries follow codes like ASME B36.10 which list important info on how different materials stand up to various pressures and temps. Looking at these standards helps keep things within safe limits for any given job. Also worth considering are past performance records and industry norms that give clues about possible shifts in operating conditions down the road. By looking ahead like this, engineers can select pipes that won't just work today but remain reliable as operational needs change. Smart planning like this saves money in the long run by avoiding expensive repairs or replacements later on.

Selecting the Right Stainless Steel Grade

Common Grades for Seamless Pipes (304, 316, 316L)

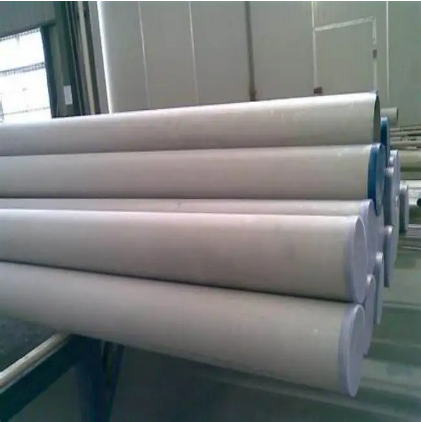

The market for stainless steel seamless pipes includes various grades, though three stand out as favorites among engineers and fabricators: 304, 316, and 316L. Grade 304 stainless steel has become something of a workhorse material across many industries. Known simply as "18/8" because it contains approximately 18% chromium and 8% nickel, this grade works exceptionally well in food processing plants and dairy operations where both corrosion resistance and easy cleaning matter most. When conditions get harsher, especially around saltwater or chlorine exposure, grade 316 becomes the go-to choice. The addition of molybdenum gives it that extra edge against chloride attacks, making it popular for coastal installations and chemical processing equipment. For those working with welds, there's also 316L stainless steel worth considering. With reduced carbon levels compared to regular 316, it prevents those pesky carbide precipitates from forming when heated during welding, thus avoiding intergranular corrosion problems down the road. This makes all the difference for projects requiring extensive joining operations.

For engineers and project managers seeking a reliable solution for environments with specific corrosion challenges, choosing the right stainless steel seamless pipe is crucial. Each grade offers unique benefits, making it vital to match the grade to the application accurately.

Corrosion Resistance vs. Cost Efficiency

When picking out stainless steel grades, finding the sweet spot between how well they resist corrosion and what they cost is pretty important. Grade 316 stands out for its ability to withstand corrosion, particularly where conditions are tough, though it does come at a steeper price tag from the start. Grade 304, which tends to be cheaper initially, often ends up costing more in repairs down the road because it doesn't hold up as well against rust and degradation. Research indicates that investing in something like 316 pays off in the long run. These high quality steels cut maintenance bills and replacements needs by around 30 percent over time since they last much longer when exposed to corrosive elements according to findings published in the Journal of Structural Engineering.

For decision-makers, understanding the trade-off between immediate expenditure and long-term savings is crucial. Reference to such studies can help justify investments in higher-grade materials where corrosive conditions justify the initial outlay, assuring stakeholders of cost-effectiveness over the lifespan of the project.

Choosing the Correct Pipe Size and Schedule

Navigating Nominal Pipe Size (NPS) Standards

The Nominal Pipe Size (NPS) system helps standardize pipe measurements across industries, mainly looking at outside diameters and wall thickness specifications. Getting familiar with NPS matters quite a bit since it directly impacts how much fluid can pass through and whether different components will actually fit together properly. Take a look at standard NPS numbers - something labeled as size 3 typically measures around 3.5 inches in actual diameter. When picking the right NPS for a job, engineers need to consider what their particular setup requires. Skipping this step often results in problems down the line such as restricted flow or sudden pressure losses that nobody wants to deal with during operation. Anyone working on high volume fluid transfer knows firsthand that going too small with NPS creates serious pressure drop issues, which means accurate sizing remains absolutely necessary if we want our systems running efficiently day after day.

Comparing Schedule 40 vs. Schedule 80

When comparing Schedule 40 versus Schedule 80 piping, the main difference comes down to wall thickness and what kind of pressure each can handle. The Schedule 40 version has thinner walls making it lighter weight and generally cheaper than Schedule 80. But when dealing with situations requiring stronger pressure resistance, most professionals go with Schedule 80 because those thicker walls stand up better under stress. Think about places like chemical plants or municipal water mains where system integrity matters a lot. For these kinds of installations, going with Schedule 80 just makes sense if we want something safe and reliable over time. Most plumbers will tell us Schedule 40 works fine around homes, but anyone running an industrial facility knows better than to skimp on materials when there's real pressure involved. Sure, Schedule 80 costs more initially, but this extra expense pays off handsomely in terms of preventing failures down the road.

Evaluating Application-Specific Considerations

Oil & Gas Industry Requirements

In the oil and gas sector, following strict standards for seamless pipes isn't just recommended it's absolutely necessary for proper installation. The rules exist because pipelines need to handle extreme pressures and harsh chemicals without failing. Stainless steel remains a top choice for many operators since these pipes don't rust easily and can last much longer than alternatives. Take offshore platforms for instance where saltwater exposure is constant stainless steel piping systems have proven their worth time after time. Industry reports show that facilities switching to premium grade stainless steel often see better performance metrics and spend less on repairs down the road. Some companies report maintenance costs dropping by as much as 30% after upgrading their pipe materials.

For more details, check Global Seamless Tubes & Pipes.

Chemical Processing and Sanitation Standards

Industries like pharmaceuticals, food production, and chemical processing all need those smooth stainless steel pipes that meet strict hygiene rules. Getting certified by organizations like the FDA or 3A isn't just paperwork it's actually pretty important for keeping products safe and pure. Stainless steel stands out because it stays clean so well, mainly since it doesn't corrode easily and can be cleaned without much hassle. When facilities use this material, they avoid contaminating their goods, which keeps customers happy and regulatory bodies off their backs. In chemical plants where things get really intense, stainless steel performs reliably under pressure while still keeping operations safe. Picking the correct grade of stainless steel pipe matters a lot though different applications call for different specifications when it comes to both cleaning requirements and how tough the environment gets.

For more information, explore Shubhlaxmi Metals & Tubes Pvt. Ltd.

Partnering with Reputable Manufacturers

Certifications and Quality Assurance

When picking a manufacturer for stainless steel seamless pipes, looking at industry certifications such as ISO and ASME makes all the difference when it comes to quality and reliability. These kinds of certifications basically show that a company follows international standards and has proper quality control systems in place something that really matters in tough industries like oil and gas where failure isn't an option. Studies have shown time and again that companies with solid quality checks tend to produce better results because their pipes just don't break down as easily under stress or harsh conditions. Take Global Seamless Tubes & Pipes for example they recently set up shop in Louisiana and made sure everyone knew about their focus on quality by sticking strictly to those recognized standards. Customers get peace of mind knowing these folks take quality seriously from day one.

Lead Times and Supply Chain Reliability

Knowing what kind of lead time a manufacturer typically has matters a lot because this directly affects when projects get done and whether operations run smoothly. When lead times stretch out too long, whole projects tend to drag on, which hits profits hard and makes it tough to hit those big picture business goals. A bunch of things play into how reliable the supply chain will be including where the factory is located, how much they can produce at once, and what happens when demand goes up or down unexpectedly. Companies looking to avoid problems should probably check out what other customers are saying about a manufacturer's track record. Looking at actual cases where manufacturers dealt with supply chain issues gives a better sense of who we can really count on. Take Global Seamless Tubes & Pipes for example. They've been setting up shop closer to where their products are needed rather than relying so much on shipping stuff across oceans. This strategy cuts down waiting periods significantly while fitting right into the current trend of bringing manufacturing back home to keep material supplies coming in consistently.

Frequently Asked Questions

What factors should I consider when selecting stainless steel seamless pipes?

Consider environmental conditions, pressure-temperature needs, corrosion resistance, cost efficiency, and the specific application area.

Why are different grades of stainless steel used for seamless pipes?

Different grades, such as 304, 316, and 316L, offer unique benefits related to corrosion resistance, durability, and suitability for various environments and applications.

What is meant by Nominal Pipe Size (NPS) standards?

NPS standards help standardize pipe dimensions, focusing on outside diameter and wall thickness, which impacts pipe capacity and compatibility.

How do Schedule 40 and Schedule 80 pipes differ?

Schedule 40 pipes have thinner walls and are lighter, while Schedule 80 pipes have thicker walls, making them suitable for high-pressure applications.

What standards are crucial for stainless steel pipes in the oil and gas industry?

Standards ensuring safe operation under high-pressure and corrosive conditions are crucial, as are certifications demonstrating quality and reliability.

Table of Contents

- Understanding Your Project Requirements

- Selecting the Right Stainless Steel Grade

- Choosing the Correct Pipe Size and Schedule

- Evaluating Application-Specific Considerations

- Partnering with Reputable Manufacturers

-

Frequently Asked Questions

- What factors should I consider when selecting stainless steel seamless pipes?

- Why are different grades of stainless steel used for seamless pipes?

- What is meant by Nominal Pipe Size (NPS) standards?

- How do Schedule 40 and Schedule 80 pipes differ?

- What standards are crucial for stainless steel pipes in the oil and gas industry?